-

Electric Wire Rope HoistElectric Wire Rope Hoist is a kind of lifting equipment commonly used in various industrial and construction fields. It is widely used in handling heavy objects and high-altitude operations. It uses electric drive to lift and move loads through wire ropes. Its core part is the lifting motor. The mot...View All Products

-

Electric Chain HoistElectric Chain Hoist is based on the driving principle of electric motor. When the electric hoist is powered on, the electric motor starts to rotate, driving the chain and hoist hook to lift and lower. The core parts of the electric chain hoist include electric motor, reducer, chain, sprocket, contr...View All Products

-

End CarriageCrane end carriage is one of the important components of the crane structure. It is part of the crane bridge system. Its main function is to carry the crane's traveling mechanism and support the overall operation of the crane. Crane end carriage bears the load of the entire crane bridge system, the ...View All Products

-

Crane AccessoriesCrane accessories are various parts related to crane operation and maintenance. They not only ensure the normal operation of the crane, but also enhance the safety, efficiency and life of the equipment. These accessories include but are not limited to hooks, slings, wire ropes, wheel sets, pulleys, ...View All Products

-

Crane Gear-motorA Crane Gear-motor is a fully integrated drive unit specifically engineered for the demanding requirements of overhead material handling equipment. It combines a high-torque electric motor with a precision-engineered reduction gearbox into a single, robust package. This critical component is the pow...View All Products

-

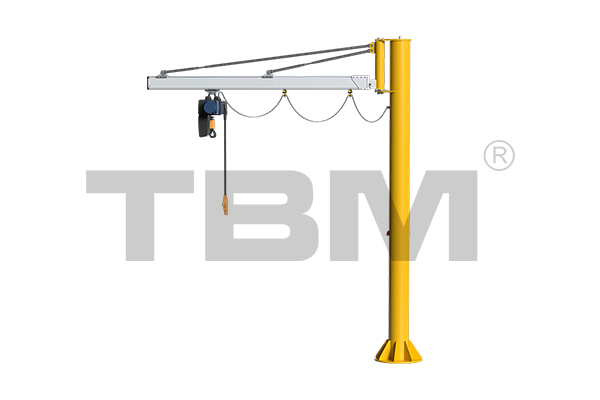

Light Crane SystemA Light Crane System is an ergonomic and highly adaptable material handling solution designed to optimize workflow in production, assembly, maintenance, and logistics environments. Unlike traditional, bulky overhead cranes, these systems are characterized by their lightweight aluminum or steel const...View All Products

As China Single Girder Hoist Manufacturers and Double Girder Hoist Factory, Zhejiang Shuangniao Lifting Equipment Co., Ltd. is a special equipment company specializing in the research and development, production, marketing and after-sales service of wire rope electric hoists. Since its establishment, the company has attached great importance to new product development and technological innovation, and has been focusing on high starting points and high configurations. In the research and development of electric hoist, while continuously introducing foreign advanced technology, it actively develops the research and development of new European-style electric hoist, and establishes the core concept of "innovation leads the future, focus on achieving wonderful", which has become the vane of domestic electric hoist development and leads The development of domestic electric hoist industry.

How to Avoid Risks Such as Overloading, Tilting, and Swaying During the Operation of Electric Lifting Hoists

Understanding the Core Safety Requirements in Electric Hoist Operation

Electric lifting hoists are widely used in industrial environments, where safety and stability are essential. Zhejiang Shuangniao Lifting Equipment Co., Ltd. has focused on high starting points and high configurations in its product development, placing emphasis on innovation and advanced technology. In practical operation, risks such as overloading, tilting, and swaying often occur due to improper use, inadequate maintenance, or mismatched equipment. To reduce these risks, operators and managers need to understand the basic principles of safe lifting and the key factors that influence hoist performance.

Preventing Overloading Through Accurate Capacity Matching

Overloading is one of the most common causes of hoist failure and accidents. It occurs when the load exceeds the rated lifting capacity, which can lead to motor overheating, brake failure, or structural damage. Shuangniao’s electric hoists are designed with high configurations and reliable components, but the first line of defense against overloading is still correct capacity selection. Before operation, the lifting capacity must be confirmed according to the load weight, lifting height, and operating frequency. In addition, operators should be aware that the rated capacity may change under different working conditions, such as high temperature, high altitude, or frequent start-stop cycles.

Using Built-in Protection Systems to Enhance Load Control

Modern electric hoists usually include protective features such as overload protection, limit switches, and brake systems. Shuangniao integrates advanced technology in its products, ensuring that these safety systems work effectively. Overload protection can stop operation or issue an alarm when the load is close to the rated capacity. Limit switches can prevent the hook from rising too high or descending too low, avoiding collisions or chain entanglement. These protection systems reduce the possibility of human error and provide a safer operational environment.

Reducing Tilting Risks Through Proper Load Centering and Slinging

Tilting occurs when the load’s center of gravity is not aligned with the lifting point, causing uneven force distribution. This not only increases the risk of the load falling, but also raises the chance of the hoist becoming unstable. To prevent tilting, operators should ensure that the load is properly centered under the hook and that the lifting points are balanced. When using slings or lifting accessories, their angles and lengths must be adjusted to keep the load stable. Shuangniao’s hoists, with their stable structural design, can help maintain balance, but correct slinging and load positioning remain essential.

Minimizing Swaying Through Controlled Movement and Smooth Operation

Swaying is caused by sudden starts, stops, or rapid directional changes during lifting. It can lead to collisions, load damage, or loss of control. To reduce swaying, operators should maintain smooth and steady control of the hoist, especially when lifting at height or moving heavy loads. Frequent start-stop operations should be avoided unless necessary. Shuangniao’s high configuration and reliable motor control help provide stable lifting performance, but the operator’s handling still plays a key role in minimizing swaying.

Ensuring Safe Lifting Through Regular Inspection and Maintenance

Maintenance is a crucial factor in preventing accidents. Over time, components such as chains, hooks, brakes, and motors can wear or become damaged. Regular inspection can identify potential risks early and prevent failures during operation. Shuangniao provides after-sales service and technical support, helping users maintain their equipment properly. Inspection should include checking the chain condition, hook deformation, brake responsiveness, and electrical systems. Any abnormality should be addressed promptly to ensure safe operation.

Training and Standardizing Operation to Reduce Human Error

Even with advanced equipment, human error remains a major factor in lifting accidents. Operators must be trained to understand safe lifting procedures, including load assessment, sling selection, and emergency response. Standardized operation procedures help ensure that every lifting task is carried out consistently and safely. Shuangniao’s focus on innovation and technology also implies that operators should be familiar with the hoist’s features and protective systems, enabling them to use the equipment correctly.

Application Scenarios and Selection Guidelines

Different production environments have different requirements for hoist performance. In workshops with frequent lifting cycles, the hoist needs to provide stable operation and reliable control. In environments with limited space, compact and efficient hoists are preferred. Shuangniao’s product strategy emphasizes high starting points and high configurations, and the company continuously introduces foreign advanced technology while developing new European-style hoists. This approach allows users to choose models that match their working conditions and reduce risks such as overloading, tilting, and swaying.

Comparison Table of Common Risk Factors and Control Measures

| Risk Factor | Cause | Control Measure |

|---|---|---|

| Overloading | Load weight exceeds rated capacity | Confirm load weight, use overload protection, select appropriate hoist |

| Tilting | Unbalanced load or incorrect slinging | Center the load, adjust sling angles, ensure balanced lifting points |

| Swaying | Sudden starts/stops or rapid directional changes | Operate smoothly, avoid abrupt movement, use stable control systems |

| Equipment Failure | Wear and tear, lack of maintenance | Regular inspection, timely maintenance, professional after-sales support |

Conclusion on Risk Reduction Strategies

Reducing risks in electric lifting hoist operation requires a combination of correct equipment selection, effective protective systems, proper load handling, smooth operation, and regular maintenance. Zhejiang Shuangniao Lifting Equipment Co., Ltd. emphasizes technological innovation and high configuration in its hoist development, which supports stable and reliable performance. However, safe operation ultimately depends on the operator’s awareness and adherence to standard procedures. By integrating advanced equipment features with practical safety practices, production teams can reduce the likelihood of overloading, tilting, and swaying, creating a safer lifting environment.

How does the turning mechanism of a turning radius electric hoist ensure stable operation?

What is the turning radius mechanism and why does it matter?

The turning radius mechanism in an electric hoist refers to the system that allows the hoist to rotate or pivot around a certain point, enabling it to cover a wider working area without needing to move the entire crane or lifting setup. In many production sites, the space is limited and the workflow is tight. If a hoist can turn smoothly, it reduces the need for repositioning equipment and speeds up handling, which is why this mechanism matters in real industrial applications.

How does Shuangniao’s design approach support stable turning?

Shuangniao has always focused on high starting points and high configurations, and this design philosophy is reflected in the turning mechanism as well. A stable turning system depends on the structural layout, the precision of the rotation parts, and the reliability of the control system. By combining advanced foreign technology with local innovation, Shuangniao’s turning radius electric hoists are built to maintain stable movement even under frequent operation and heavy load conditions.

What are the key components that keep the turning mechanism stable?

At the core, a stable turning mechanism requires strong mechanical support, smooth rotational bearings, and a reliable drive system. The bearing system must handle both the vertical load and the horizontal turning forces, while the drive system must provide consistent torque. In a turning radius hoist, these parts must work together without producing excessive vibration or friction, otherwise the hoist may shake, generate noise, or wear out faster.

How does the load distribution affect turning stability?

When a hoist turns with a load, the load creates additional forces that affect the entire structure. If the turning mechanism is not designed properly, the load can cause uneven stress distribution, which can lead to wobbling or instability. A well-designed turning mechanism keeps the load center aligned and ensures the rotation is smooth. This is especially important in high-configuration hoists where the load capacity and duty cycle are higher, making the stability requirements more strict.

How does the control system influence turning stability?

The turning radius mechanism does not only rely on mechanical parts; the control system plays a major role. A stable control system can manage the speed and acceleration of rotation, preventing sudden starts or stops that may cause swinging. Shuangniao’s emphasis on new product development and technology innovation helps ensure that their hoists have control systems that support smooth and stable turning, especially in continuous or high-frequency operations.

What are the typical risks if the turning mechanism is not stable?

If the turning mechanism is unstable, several issues can occur. The hoist may generate vibration that accelerates wear on the bearings and the drive system. The load may swing, which increases the risk of collision with nearby objects or workers. Over time, instability can also lead to structural fatigue. In industrial environments where safety and productivity are both critical, these risks can affect the entire production line.

What role does the European-style design concept play in the turning mechanism?

European-style electric hoists typically emphasize compact structure, improved mechanical efficiency, and more balanced load handling. Shuangniao’s focus on developing European-style hoists means the turning mechanism is designed to integrate smoothly with the overall hoist structure. This integration helps reduce unnecessary mechanical stress and improves the consistency of turning performance.

How can users evaluate the stability of a turning radius hoist?

Users can evaluate stability by checking the hoist’s performance under load during turning, observing whether the rotation is smooth and whether the load swings noticeably. Another way is to monitor noise and vibration during operation. A stable mechanism should operate quietly and without visible shaking. In addition, inspecting the bearing system and the drive system for signs of wear or overheating can also help evaluate stability over time.

How do maintenance and inspection affect turning stability?

Even the best-designed turning mechanism needs proper maintenance. Regular lubrication, inspection of bearings, and checking for loosened parts are essential. Shuangniao’s after-sales service support can help users maintain their hoists and address issues early. If users neglect maintenance, the turning mechanism may become loose or worn, which reduces stability and increases safety risks.

Turning mechanism factors affecting stability

| Factor | What it affects | What users should check |

|---|---|---|

| Bearing system | Rotation smoothness and load support | Wear, noise, heat |

| Drive system | Torque consistency and acceleration control | Motor performance, vibration |

| Structural layout | Load distribution and stress balance | Deformation, loose fasteners |

| Control system | Start/stop behavior and speed control | Response stability, control accuracy |

Why does Shuangniao’s turning radius hoist lead the market in stable operation?

Shuangniao’s long-term focus on innovation and technology makes its hoists more capable of handling real industrial needs. By combining advanced foreign technology with local R&D, the company has developed hoists that meet the requirements of modern production lines. The turning mechanism is one of the key areas where this design philosophy shows results, because stable turning is not only about rotating a structure, but about ensuring safety, consistency, and long-term durability.

English

English 中文简体

中文简体