Aluminum Light Cranes

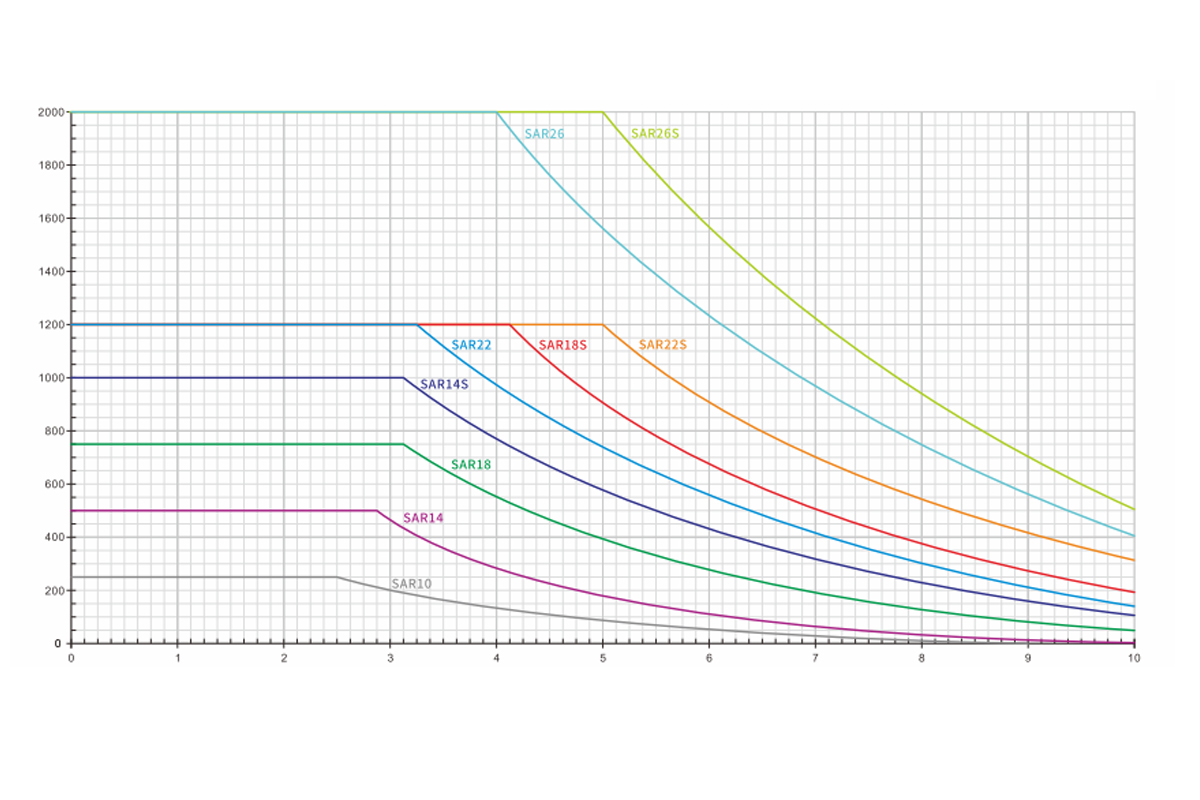

There are five different specifications of aluminum alloy tracks. Precision processed aluminum alloy profiles and structural components are easy to install, modular, and maintain smoother operation. The sealed design of aluminum alloy tracks is lightweight but has high bending strength and better wear resistance. Due to surface positive electroplating treatment and its own anti-corrosion properties, this structure is used in clean workshops and automotive production lines, food, and point operations. The lighter self weight is a factor worth considering.

The aluminum alloy track has undergone anodizing and anti-corrosion treatment, with good wear resistance, high bending strength, light weight, low friction resistance (50% lighter than KBK traditional track), modular design, easy installation, 5 models to choose from, single rail suspension, single beam, double beam, telescopic beam, combination self standing and other structures to choose from. Flexible and rigid connection installation methods are optional, and the track joints are seamlessly connected. The manual/electric operation noise is low, and the nylon wheels make the track wear low. It runs quietly and smoothly, suitable for larger spans.

- Specification

- About TBM

- Contact Us

|

Drive Mode |

Manual/Electric/Semi-automatic |

|

Lift Capacity |

250/500/1000/2000kg |

|

Type |

Monorail/Single-beam/Dual-beam/Multi-support |

|

Fixed Rail Length |

Customizable |

|

Lifting Height |

Customizable |

|

Lifting Device |

Hoist/Pneumatic Balancer/Intelligent Crane |

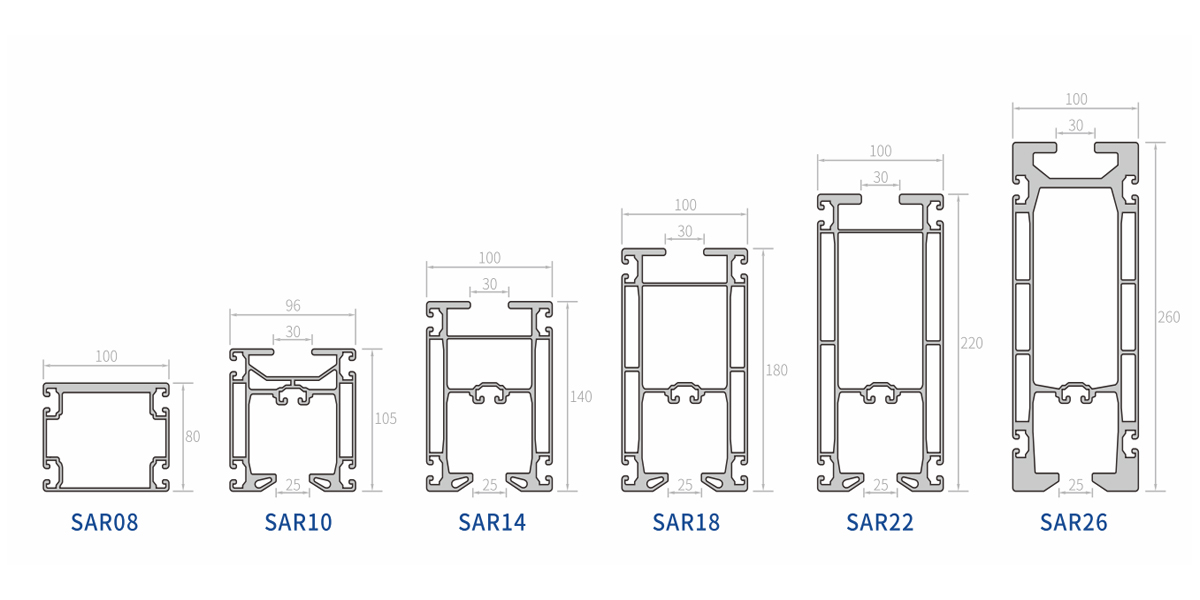

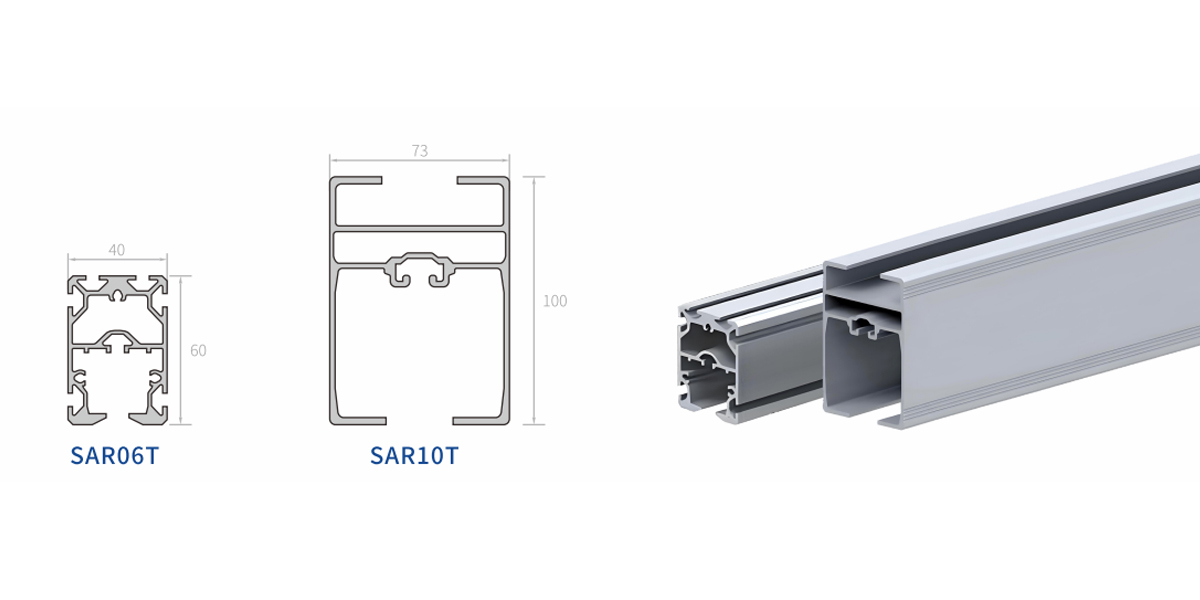

| Model | Description | Weight in meters | Moment of inertia of area | Flexural modulus |

| SAR08 | Aluminum, anodized | 4.1KG/m | 152cm^4/202cm^4 | 30cm^3/40cm^3 |

| SAR10 | Aluminum, anodized | 5.3KG/m | 233cm^4/209cm^4 | 42cm^3/44cm^3 |

| SAR14 | Aluminum, anodized | 7.4KG/m | 600cm^4/330cm^4 | 85cm^3/67cm^3 |

| SAR18 | Aluminum, anodized | 8.9KG/m | 1206cm^4/433cm^4 | 132cm^3/85cm^3 |

| SAR22 | Aluminum, anodized | 10.5KG/m | 2183cm^4/520cm^4 | 203cm^3/112cm^3 |

| SAR26 | Aluminum, anodized | 17.5KG/m | 5398cm^4/851cm^4 | 407cm^3/179cm^3 |

ALUMINUM LIGHT COMPONENTS

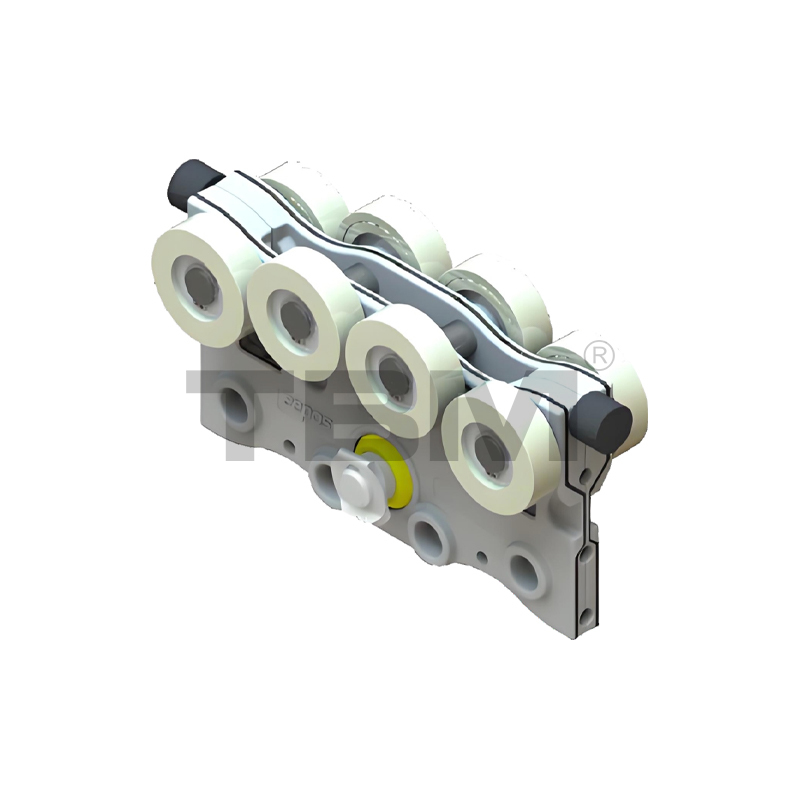

AETO1 Track Trolley

■ The trolley is die-cast/forged from high-strength, wear-resistant nylon for smooth gliding and easy operation.

■ Two rows of upper and lower rollers provide protection against prying and misalignment.

| Specifications | Loading | Notes |

| AET01 | ≤500KG | Die-cast standard version |

| AET02 | ≤500KG | Forged standard version |

| AET03 | ≤600KG | Forged high-strength version |

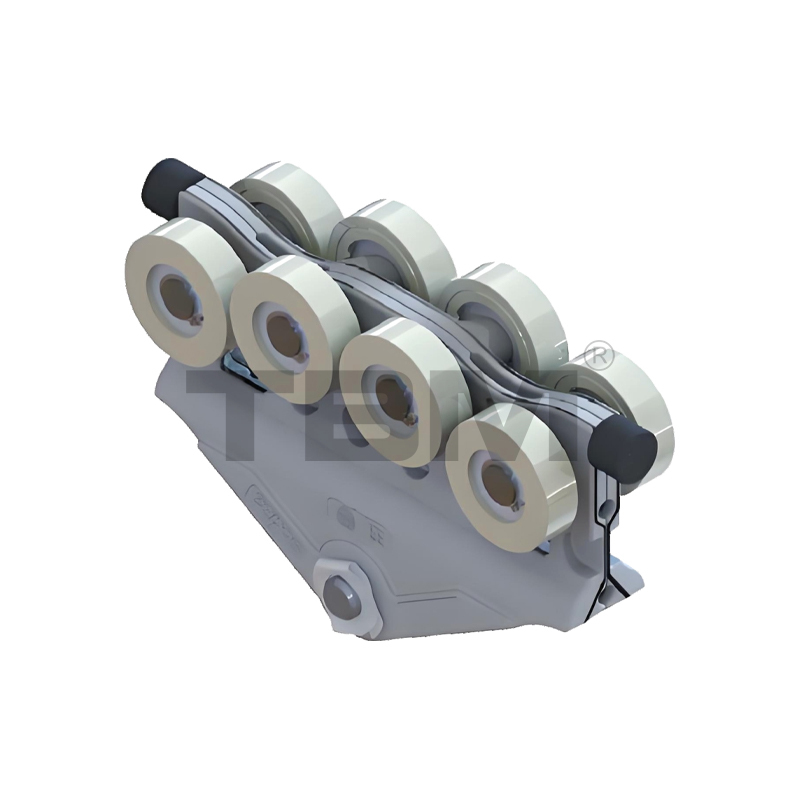

AHT01/02 Main Beam Pulley (Cast/Forged Aluminum, Triangular)

■ The trolley is die-cast/forged from high-strength, wear-resistant nylon for smooth gliding and easy operation. Two rows of upper and lower rollers provide pry-resistant and anti-bias protection.

| Specifications | Loading capacity | Notes |

| AHT01 | ≤500KG | Die-cast standard version |

| AHT02 | ≤500KG | Forged standard version |

| AHT03 | ≤600KG | Forged high-strength version |

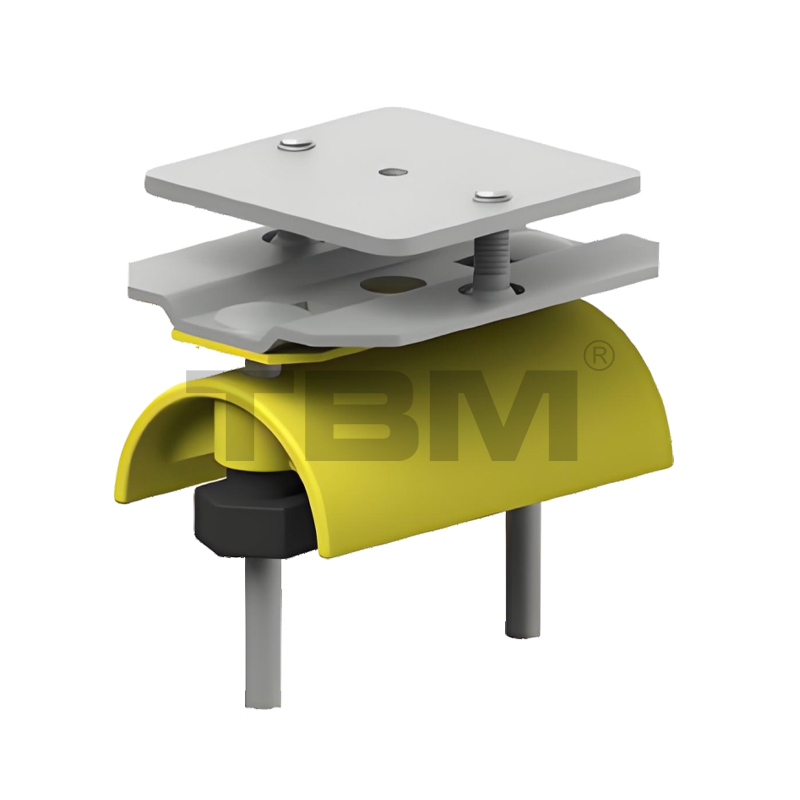

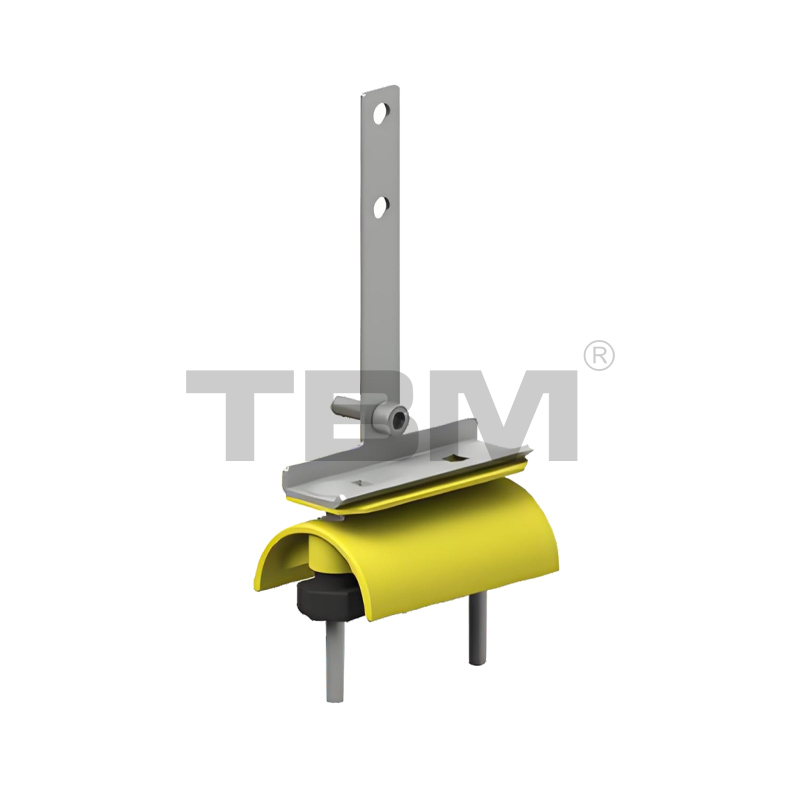

ALP1510F Flexible Track Lifting Point

■ Flexible lifting points are commonly used in track systems. The connection between the lower part of the lifting point and the flange plate utilizes a spherical structure. This flexible structure provides high load-bearing capacity.

■The inertial force generated when the main beam or hoist moves and impacts the end allows for slight sway on the fixed rail.

Note: Other sizes are available upon request. Please ensure you confirm the lifting point selection when placing your order to avoid unnecessary complications during on-site installation.

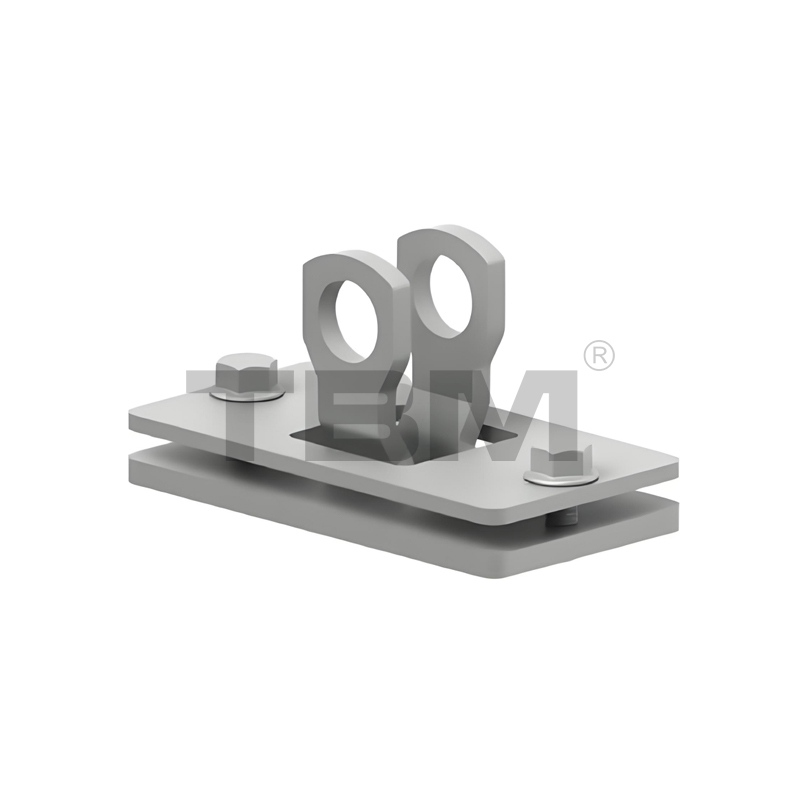

ALP1510R Rigid Rail Lifting Points

■Rigid lifting points are typically used for applications such as manipulators and telescopic beams that require upward force. Due to their structural nature, they prevent the entire machine from shaking during use. Currently, our default lifting point type is rigid.

Note: Other sizes are available upon request. Please ensure you confirm the lifting point selection when placing your order to avoid unnecessary installation complications.

AGL90 Rail Lifting Lug (90°)

■ Connection method for the main beam and rail trolley.

■ Single load capacity: 600 kg

■ The main beam is connected to the fixed rail at a 90° angle.

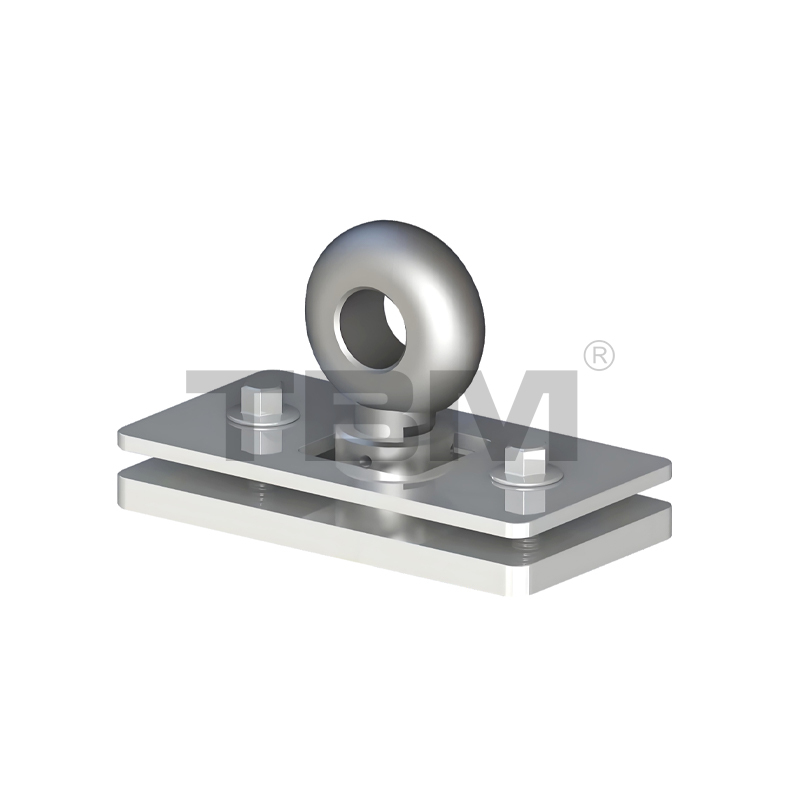

AGL360 Track Lifting Ring (360°)

■The ring features a curved step at the bottom for flexible swinging. It is primarily used for connecting main beam lifting points in tandem trolley configurations.

■A single lifting ring has a load capacity of 1000 kg and is manufactured using a red satin finish.

AGL00 Rail Lifting Lug (0°)

■Connects the main beam to the rail trolley.

■Single load capacity: 600 kg

■The main beam is connected to the fixed rail at a 0° angle.

■Generally used for lifting lugs on the lower rail of telescopic beams.

ATCO1 Tandem Trolley Connector Plate

■ For loads exceeding 500 kg or spans greater than 6 meters, a tandem trolley system is required. This system offers increased load capacity and a wider range of applications.

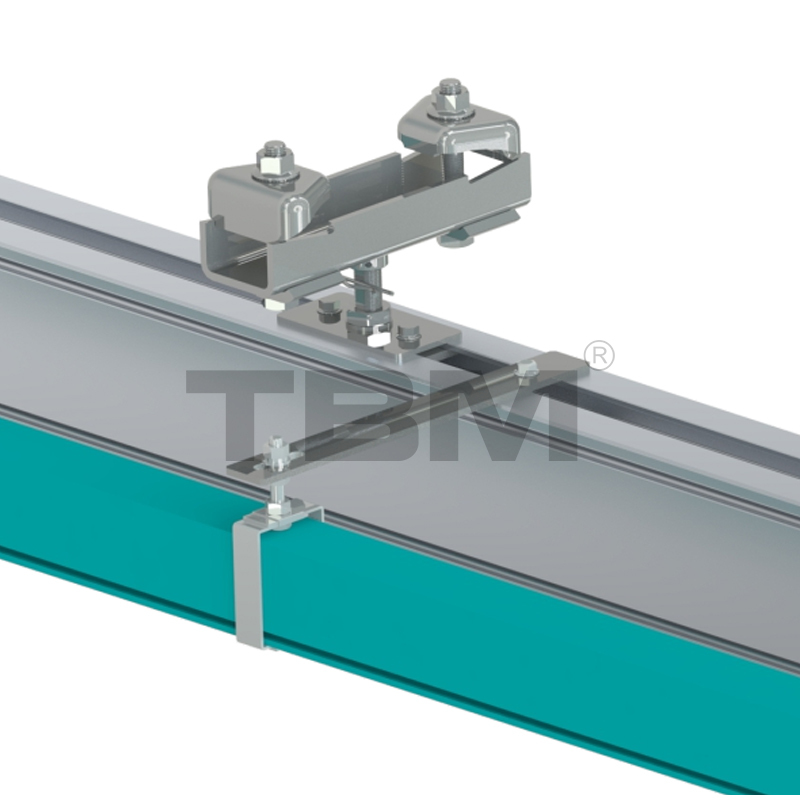

ARCO1 Rail Connectors

■ Long rails require multiple rails to be joined together. The four-piece split rail connectors allow for universal use across the entire rail range.

ACS01 Reinforcement Rail Connector Plate

■When reinforcing the main beam, the distance between the main beam rail and the reinforcement rail connector plates should not exceed 1500mm.

AFS01 Fixed Stop

■The latch at the end of the track prevents the trolley from sliding off the track.

AAS01 Adjustable Stop

■The adjustable stop is snapped into a notch on the rail's inner cavity, allowing for arbitrary adjustment of the stop position.

AMS01 Intermediate Movable Stop

■Intermediate Movable Stops are movable stops between two adjacent beams in multi-girder applications. They prevent the two beams from being too close together and potentially causing collisions between the hoist and the workpiece.

Track End Caps

■These caps seal the ends of the tracks, preventing dust and foreign matter from entering the track and providing a decorative aesthetic.

| Specifications | Loading capacity | Notes |

| AEC10 | SAR10 | Plastic/Aluminum |

| AEC14 | SAR14 | Plastic/Aluminum |

| AEC18 | SAR18 | Plastic/Aluminum |

| AEC22 | SAR22 | Plastic/Aluminum |

| AEC26 | SAR26 | Plastic/Aluminum |

ADP-R/G/H Secondary Protection

■To prevent unexpected situations, we've installed secondary protection devices on every fixed rail, every main beam, and every hoist.

They are categorized as follows:

| Name | Models | Notes |

| Track secondary protection | ADP-R | Wire rope length 1 meter |

| Main beam secondary protection | ADP-G | Wire rope length 0.4 meter |

| Hoist secondary protection | ADP-H | Wire rope length 0.4 meter |

ACT01/AAT01 Cable/Tube Trolley

■This is a travel pulley used to hold cables or tubes when they are being dragged along a track.

ACE01/AAE01 Cable/Tube End Clamp

■This device secures cables or tubes to the end of a track.

ACH01/AAH01 Cable/Tube Pulling Bracket

■Used for securing and pulling cables/tubes while traveling on rails or hoist pulleys.

AWS01 Wire Rope Bracket

■ Used to secure and tighten the wire rope used to hang spiral air hoses.

ASS01 Busbar Bracket

■A hanging bracket for power busbars, with flexible adjustment.

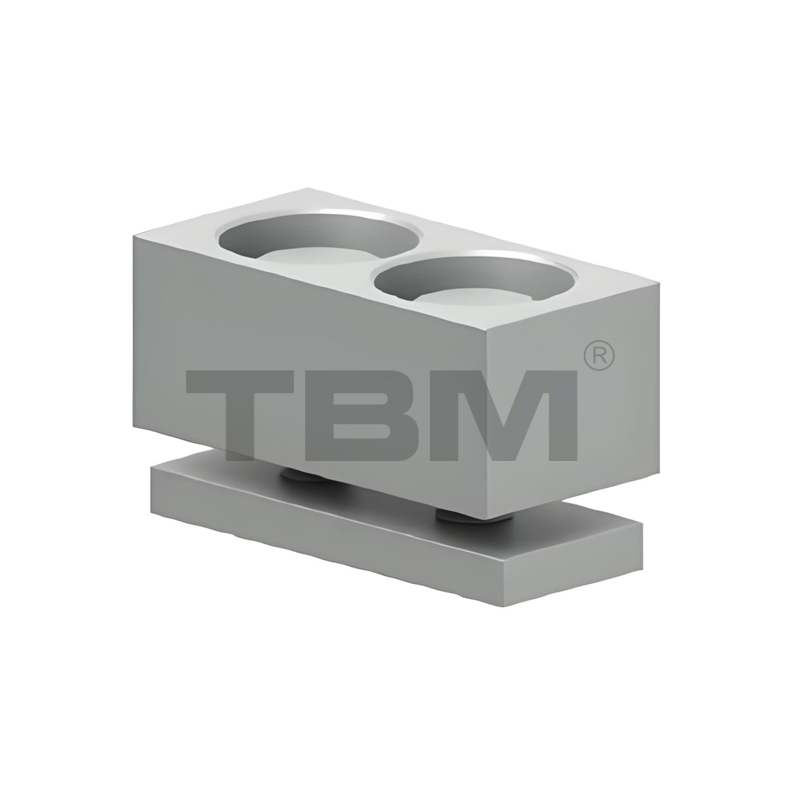

ACD01 Double Girder Spacer Connector

■Used to connect and secure track spacers at both ends of a double-girder structure. Four separate pieces are compatible with all track spacers.

ATC01 Double-Girder Trolley Frame

■ This trolley frame is used to mount a hoist on a double-girder structure. The default distance between the two beams is 700mm.

■ If the double beams are mounted on a T-arm or manipulator structure, other trolley frame structures are available.

ALM10 Main Girder Lift Module

■Used to lift the main girder rails, lowering the overall headroom and increasing the lifting height.

| Models | Corresponding orbits |

| ALM10 | SAR10 |

| ALM14 | SAR14 |

| ALM18 | SAR18 |

| ALM22 | SAR22 |

| ALM26 | SAR26 |

AEB01 End Buffer

■Designed to cushion the impact of a rail pulley or hoist pulley momentarily due to inertia, reducing impact on the track and overall structure.

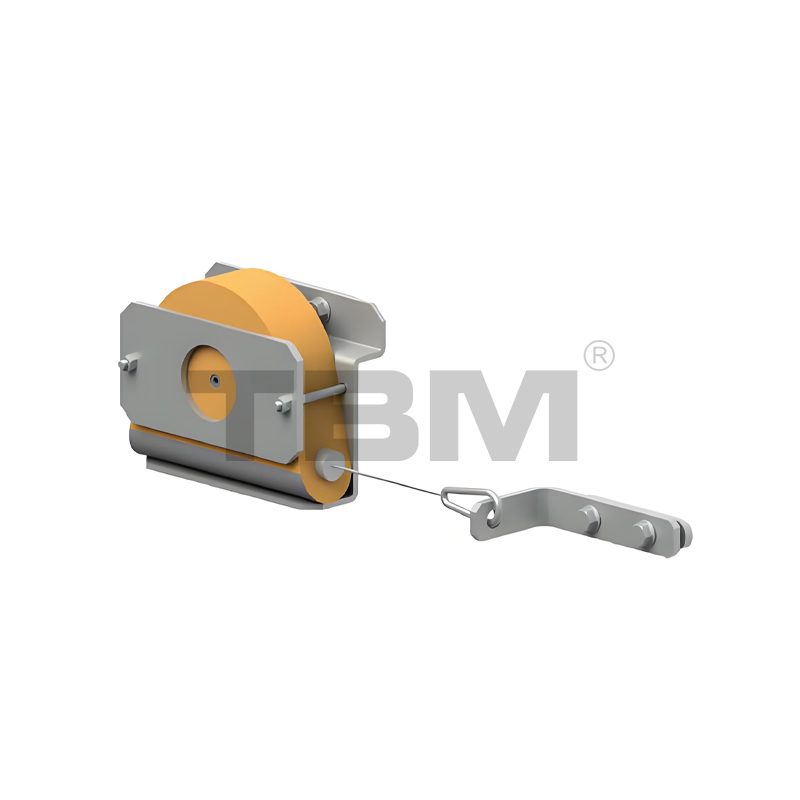

ABT01 Telescopic Beam Rebound Device

■ This device actively rebounds the overhanging track when the telescopic beam is in use, ensuring the overhanging beam always stays within the upper track to prevent accidental collisions.

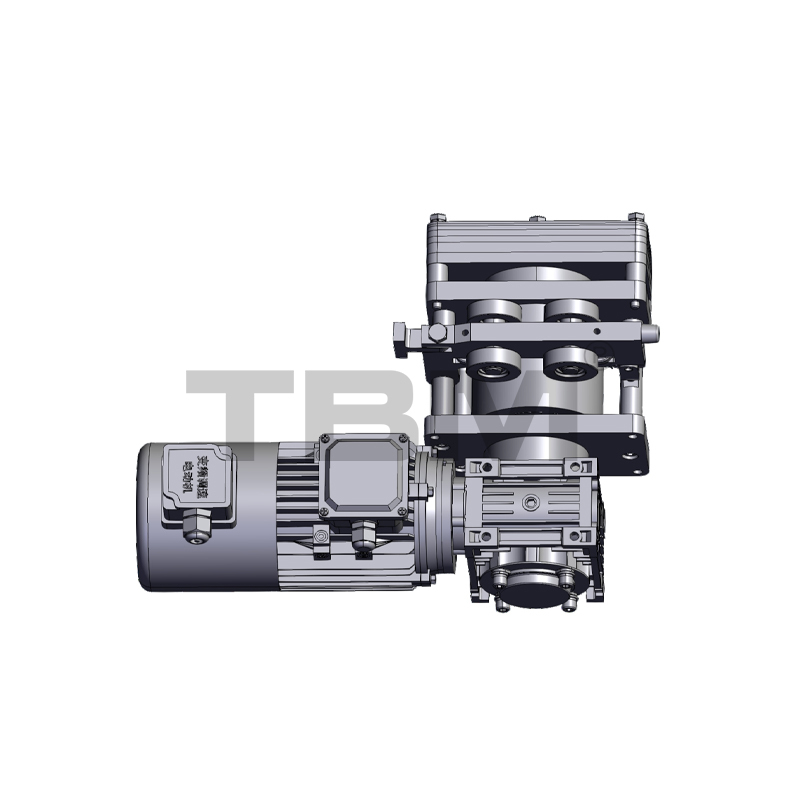

AEDO1 Electric Trolley

■ When the travel mode is electric, the main beam and hoist drive unit. The motor can be selected from domestic or imported brands.

■ Default travel speed: 5-20m/min (variable frequency dual speed)

| Model | Notes |

| AED01 | Standard premium brand motor |

| AED02 | High-end SEW motor/other |

| AED02 | Custom servo drive motor |

AEB01 Electronic Control System

■ Drive control unit. Depending on customer requirements, the selected configuration may vary.

■ The default control system is variable frequency.

| Model | Notes |

| AEB01 | Standard configuration: premium domestic brand components |

| AEB02 | High-end imported brand components |

| AEB03 | Customized servo drive configuration |

Tool Rail

The general specifications of aluminum alloy gantry are as follows:

| Load | Width | Adjustable height | Track Type | Special Notes |

| 250KG | 2000mm | 1800-2600mm | Folding Fixed |

Default color Aluminum alloy color |

| 500KG | 2300mm | 2600-3300mm | ||

| 1000KG | 3000mm | 3200-4300mm | ||

| 2000KG | 4000mm | Other sizes available |

Recommended Products

-

SHA8 Low-headroom Electric Wire Rope Hoist

-

SHA8 Double Girder Electric Wire Rope Hoist(Double reel)-BZ Type

-

SHA8 Double Girder Electric Wire Rope Hoist(Single Reel)-BS Type

-

SHA8 Winch

-

SHA7 Low-headroom Wire Rope Hoist

-

SHA7 Double Girder Electric Wire Rope Hoist

-

SHA7 Standard headroom Wire Rope Electric Hoist

-

Crane End Carriage

-

Crane Wireless Remote Control

-

Crane Conductor System

-

Crane Festoon System

-

Crane Wheel Block

Zhejiang Shuangniao Lifting Equipment Co., Ltd. is a special equipment company specializing in the research and development, production, marketing and after-sales service of wire rope electric hoists. Since its establishment, the company has attached great importance to new product development and technological innovation, and has been focusing on high starting points and high configurations. In the research and development of electric hoist, while continuously introducing foreign advanced technology, it actively develops the research and development of new European-style electric hoist, and establishes the core concept of "innovation leads the future, focus on achieving wonderful", which has become the vane of domestic electric hoist development and leads The development of domestic electric hoist industry.

English

English