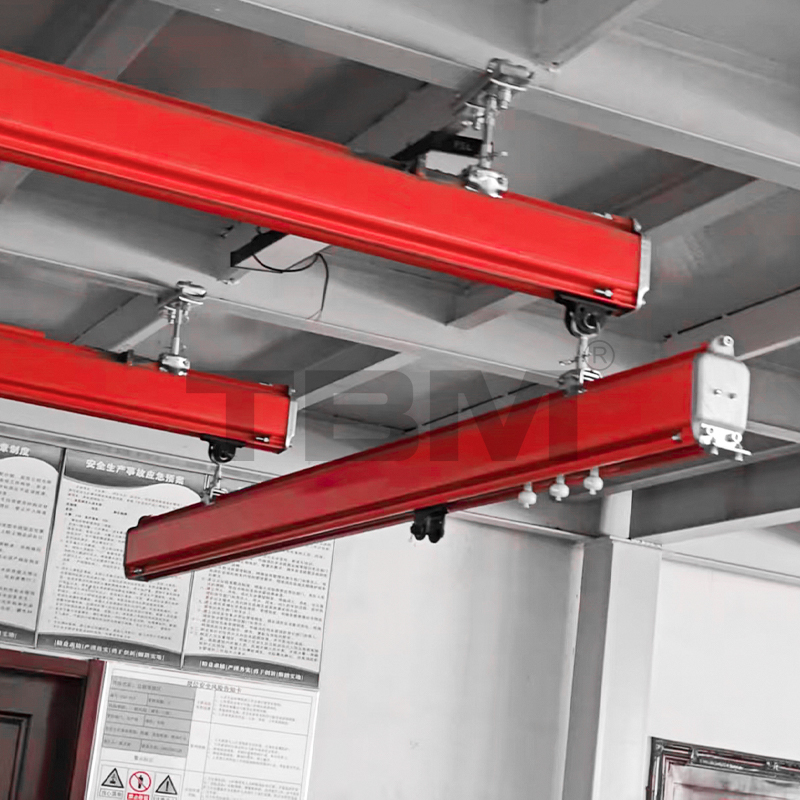

KBK Crane Systems

KBK cranes include various forms of cranes such as monorail, single beam, double beam, and telescopic beam. The flexible lifting capacity is 0.125t-2t, and the application range is very wide, especially suitable for modern production conveyor lines. The lifting system is lightweight, flexible, reliable, and stable, and all components use standard modules, which can ensure large-scale, high-quality production and easy maintenance in the later stage. KBK tracks and various standard modules can be connected by bolts, which is easy to install, cost-effective, and can greatly save factory space and area, thereby saving costs, improving efficiency, and further increasing enterprise benefits.

- Specification

- About TBM

- Contact Us

Product Advantages

·Easy to install and lightweight

·Composed of KBK standard components, it enables you to quickly and reliably transport materials within specific areas and locate various components.

·The main beam can be composed of one or two parallel standard sections, making it effortless to construct, expand, or renovate.

· Multiple points, multiple beats

· It can save factory space and area, reduce energy consumption, improve enterprise efficiency, have strong adaptability, and lower costs.

Product parameters

|

Drive mode |

Manual/electric/semi-automatic |

|

Lifting capacity |

250/500/1000/2000kg |

|

Type |

Monorail/Single Beam/Double Beam/Multi pivot |

|

Fixed rail length |

Customized according to actual needs |

|

Lifting height |

Customized according to actual conditions |

|

Lifting device |

Hoist/pneumatic balancer/intelligent crane |

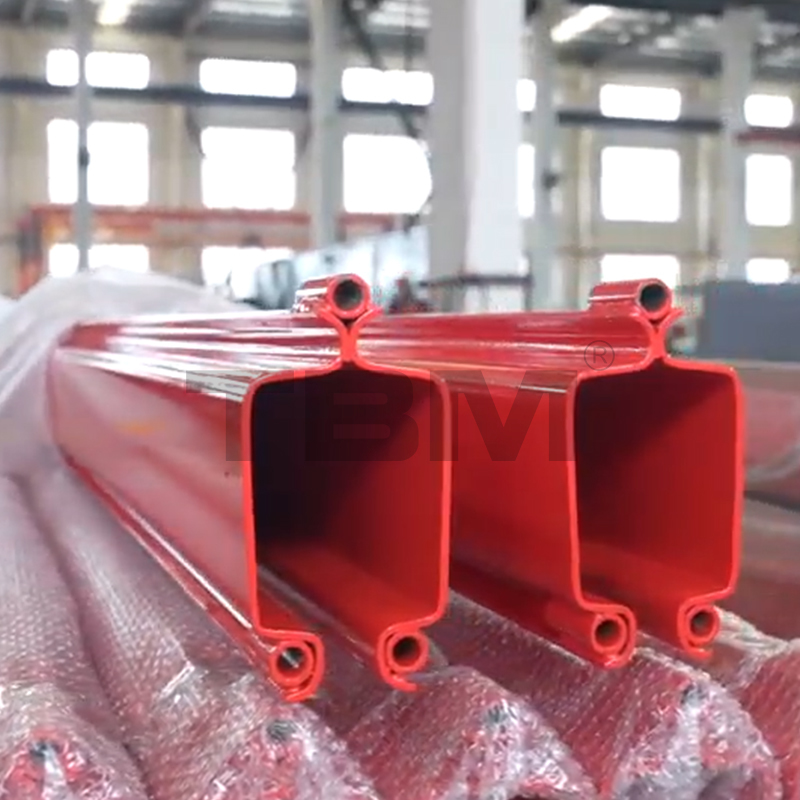

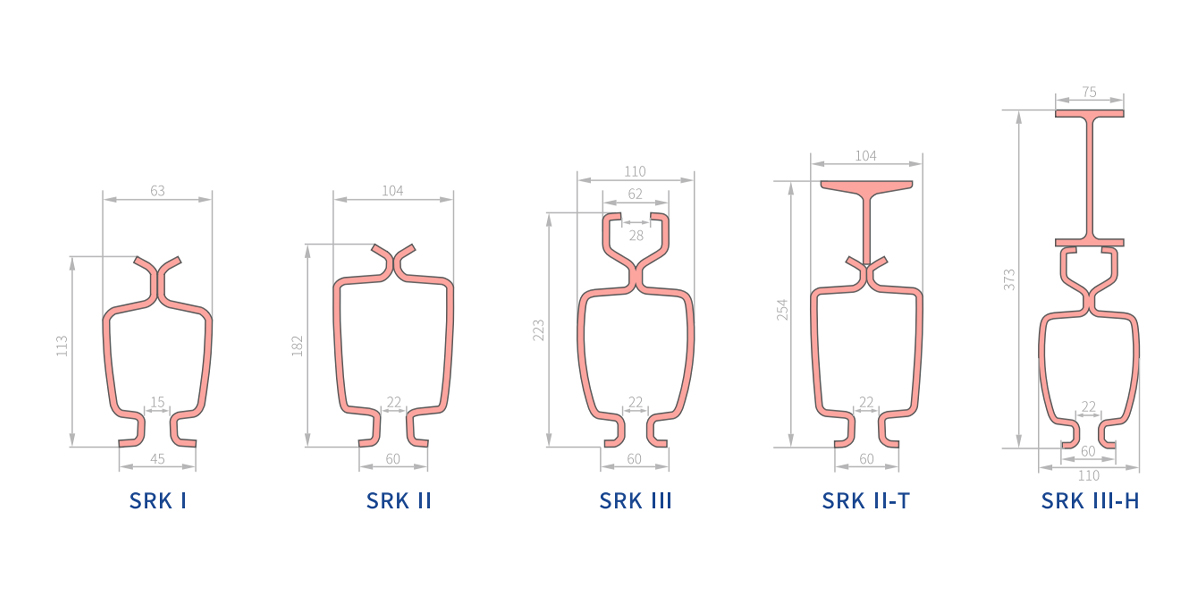

| Model | Rail Material | Weight per meter | Cross-sectional area | Moment of inertia | Fixed Rail Load | Main beam load | Standard Size | Standard color |

| SRKI | High-strength mild steel | 8kg/m | 9.12cm² | 84cm⁴ | 125kg (within 2m of the lifting point) |

The following graph | 6m | RAL2002 |

| SRK II | High-strength mild steel | 17kg/m | 20.08cm² | 651cm⁴ | ≤2000kg | The following graph | 6m | RAL2002 |

| SRK Ⅲ | High-strength mild steel | 24.5kg/m | 31.32cm² | 1390cm⁴ | >2000kg | The following graph | 6m | RAL2002 |

| SRK II-T | High-strength mild steel | 26.6kg/m | 33.88cm² | 2380cm⁴ | Not equipped with fixed rails | The following graph | Custom Size | RAL2002 |

| SRK Ⅲ-H | High-strength mild steel | 38.6kg/m | 49.12cm² | 5900cm⁴ | Not equipped with fixed rails | The following graph | Custom Size | RAL2002 |

| Recommended maximum lifting point spacing: 1t<load≤2t, spacing≤0.9m; 0.5t<load≤1t, spacing≤1.5m; load≤0.5t, spacing≤2m; Note: 1. Within 250mm on either side of the joint, one lifting point is required on each side. 2. The standard track length is 6m per track, and a single track requires at least two lifting points. 3. The above configuration rules are based on SRKli track. |

||||||||

KBK COMPONENTS

KMT I/KMTII SRK Single Trolley

■Designed load: 125kg/250kg

■KMTI is compatible with SRKI track, KMTII is compatible with SRKISRKII track

[The trolley wheels are made of high-strength nylon with a specific wheel angle, perfectly fitting the track tread. The trolley automatically centers during operation. The trolley is equipped with a guide wheel structure to avoid friction with track openings and increase running resistance. Two horizontally positioned wings ensure that the trolley will not fall off the track in the event of a malfunction, fully ensuring safety.]

KMTI01 Double Trolley

■Designed for loads of 500kg-1000kg

■Adaptable to SRKII and SRKIII track types. This double trolley design is used when loads are higher.

■Can be used for main beam or end beam applications.

KMTII02 Single-Girder Rigid End Beam Trolley

■ Designed for loads of 500kg-1000kg

■ Compatible with SRKII SRKII track types

■ This electric mid-beam trolley features a rigidly connected structure, preventing twisting during operation.

KMTII03 Single-Girder Rigid End Beam Trolley Set

■ Designed for loads of 500kg-2000kg

■ Compatible with SRK II and SRK II II rails

■This trolley is an extended version of the KMTI102. It is suitable for applications where a single main beam exceeds 9 meters and requires a trolley set to extend the end beam length. It also supports single-girder end beam trolleys with loads up to 2000kg.

KMTI04 Dual-Girder Rigid End Beam Trolley

■Designed Load: 250kg-1000kg

■Compatible with SRK I and SRK II Track Types

■This dual-girder end beam trolley features a fixed trolley plate spacing, ensuring the distance between the two beams remains constant.

KMTI05 Double-Girder Rigid End Beam Trolley

■Designed Load: 500kg-2000kg

■Compatible with SRK I and SRK II Tracks

■This trolley is an extended version of the KMTII04, suitable for double-girder structures with a main beam exceeding 9 meters or a load of 2000kg.

MTII11 Electric Trolley

■ Motors are available in both domestic and imported brands.

■ Compatible with SRKI and SRK II track types.

■The drive unit for the SRK system's main beam or hoist uses friction between the rubber-coated wheels and the track bottom to pull the main beam and hoist. It is suitable for applications with large spans and heavy loads, where manual lifting is difficult. The choice depends on the customer's specific needs.

KMTII 12-Girder Trolley

■Default twin-girder center spacing is 700mm

■For SRKI and SRKII double-girder track structures, this hoist-mounted trolley evenly distributes the hoist load across the two main beams.

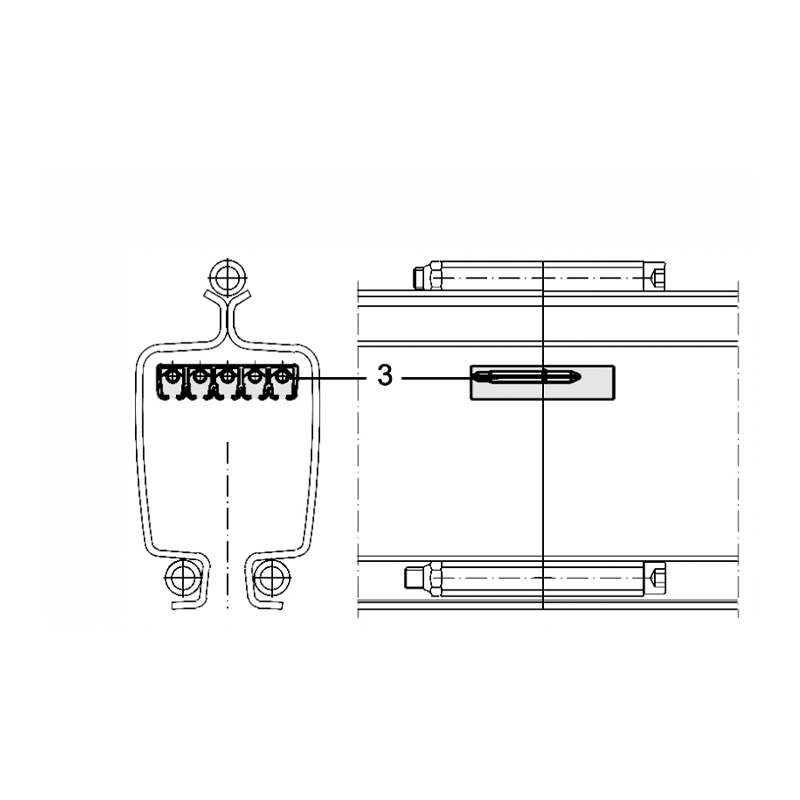

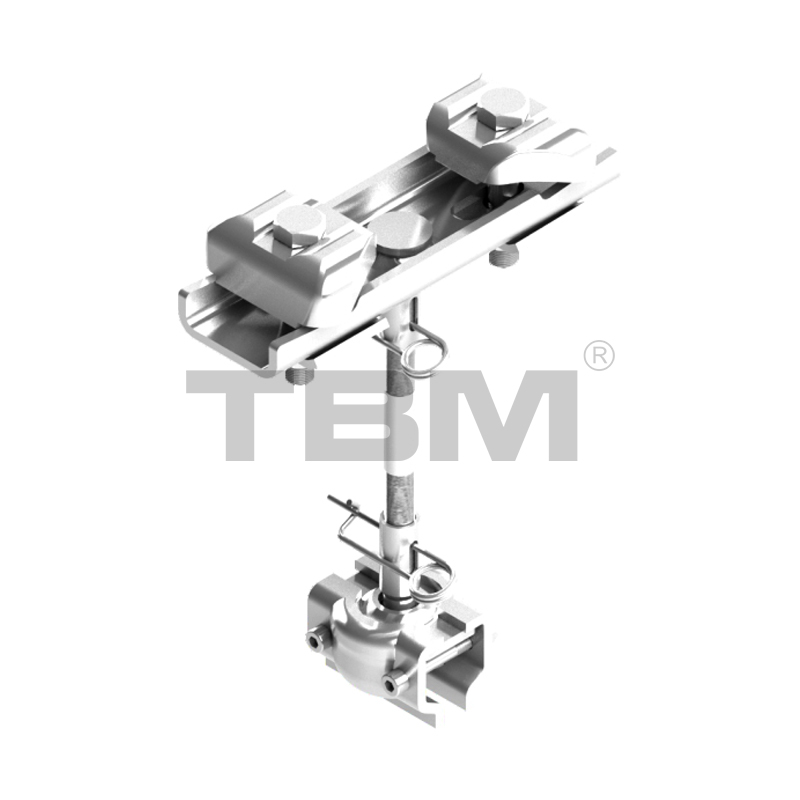

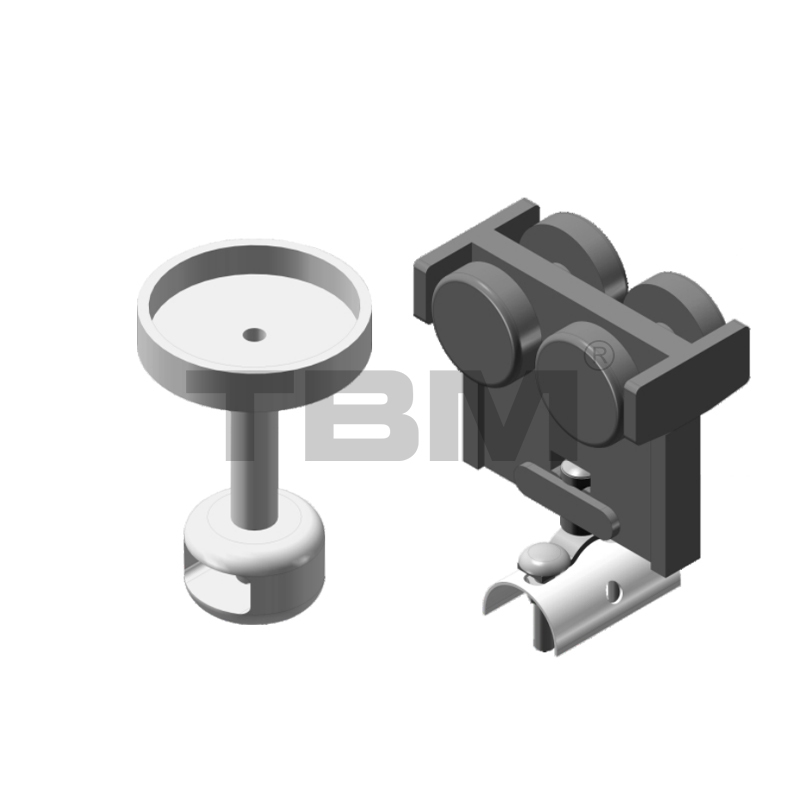

KLP1312 Track Lifting Point

■ Track lifting points vary in width and lead screw length, allowing for various combinations:

KLP1312: Suitable for widths of 60-130mm, lead screw length 120mm

KLP1512: Suitable for widths of 60-150mm, lead screw length 120mm

KLP2512: Suitable for widths of 150-250mm, lead screw length 120mm

KLP1322: Suitable for widths of 60-130mm, lead screw length 220mm

KLP1522: Suitable for widths of 60-150mm, lead screw length 220mm

KLP2522: Suitable for widths of 150-250mm, lead screw length 220mm

■ Track lifting points feature flexible connections, allowing for movement due to impact during track operation and preventing binding caused by rigid connections.

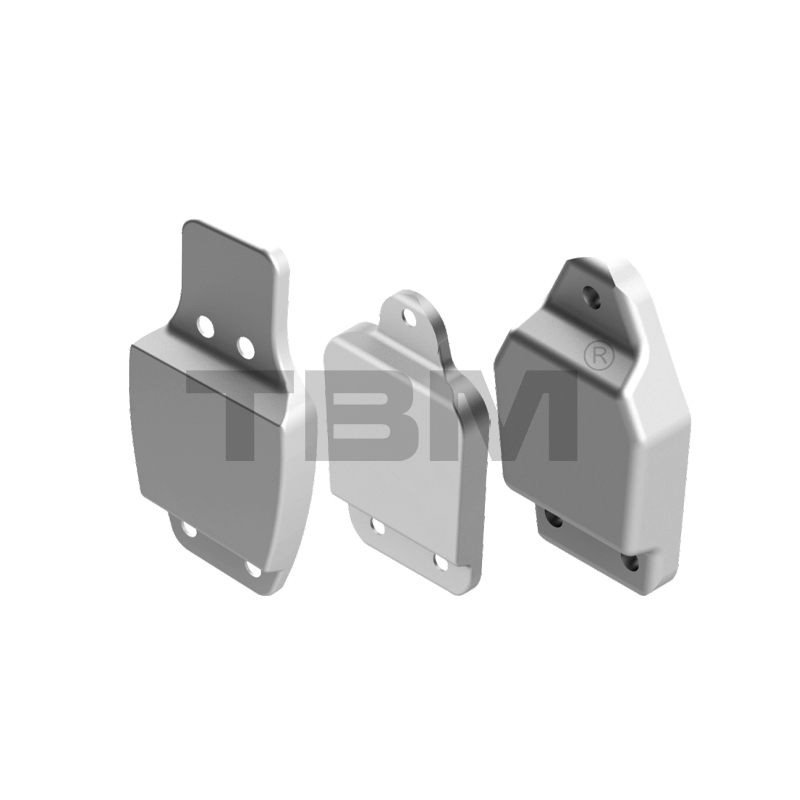

KECII Track End Cap/KCEII End Cable Clamp

■Depending on the track model, the end cap and cable clamp models vary:

KECI Track End Cap/KCEI End Cable Clamp

KECII Track End Cap/KCEII End Cable Clamp

KECII Track End Cap/KCEII End Cable Clamp

■The track end cap (including the SCRli end cap retainer) seals the end of the track to prevent moving components from falling. It has anti-collision rubber blocks to cushion impacts.

The end cable clamp secures the cable at the end of the track.

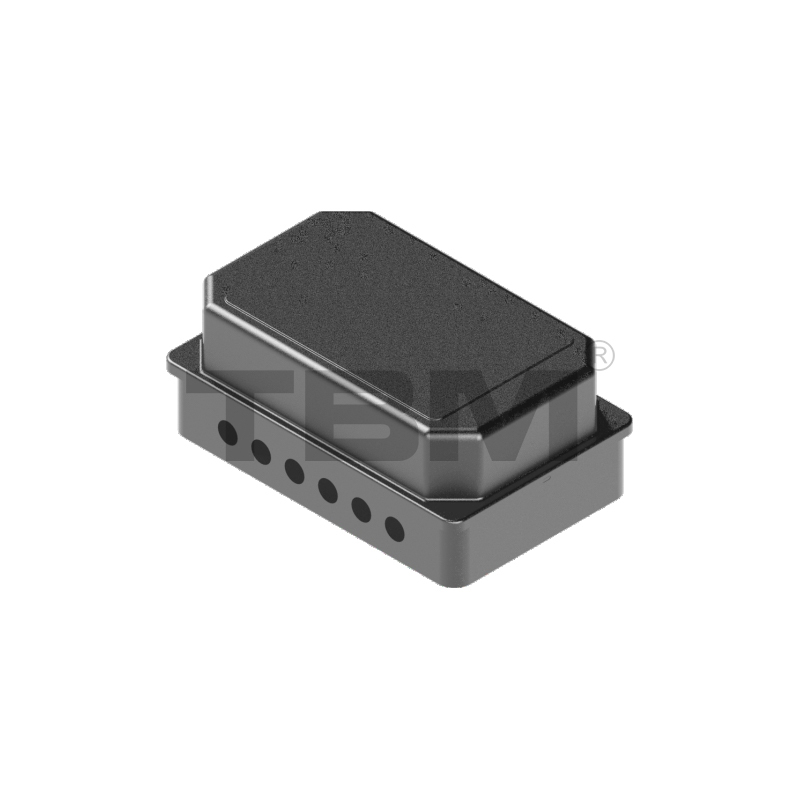

KEB01 electrical control box

■Internal components are optional, and both domestic and imported inverters and components are available. The selection is tailored to the customer's needs.

■The trolley and trolley electrical boxes are typically separate by default.

■The electrical control box is the electrical control unit in a fully electric system and is customized based on the hoist (control voltage) and control method (handle control, remote control), among other factors.

KDP-G Secondary Protection

■Depending on the object being protected, it can be divided into the following three types:

KDP-R Track Secondary Protection

KDP-G Main Beam Secondary Protection

KDP-H Hoist Secondary Protection

■ KBK track rails and hoists involved in movement and loads are equipped with secondary protection to prevent accidental detachment. Holes are reserved on the track and main beam for installation of secondary protection.

KASI/KSAII/KASII Built-in Stopper

■ Compatible with SKRI, SKRII, and SKRII track types.

■ When cables are piled up at the end of the track, the cable sliders/pulleys will be pressed together. The built-in stopper prevents the load-bearing trolley from striking the cable sliders/pulleys.

■ Hole positions are factory-drilled based on the number of cable sliders/pulleys and can be adjusted during construction based on actual site conditions.

KCS01 Cable Slider / KCT01 Cable Pulley

■ The standard default cable slider is used for manual series, and the cable pulley is used for electric series.

■The cable suspension system built into the track includes cable sliders and cable pulleys, which are used to drag the cable during travel.

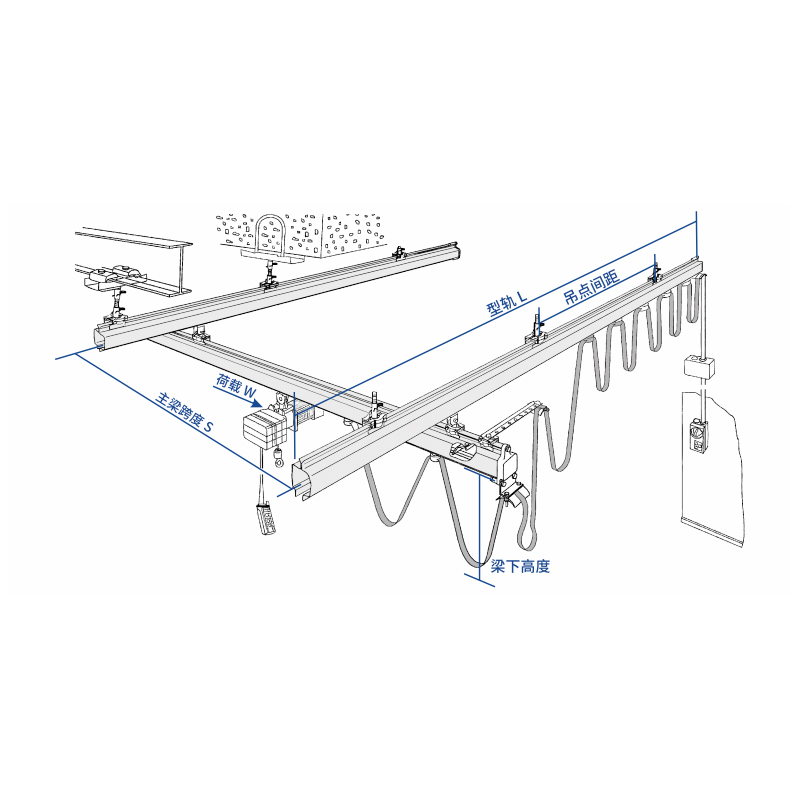

CUSTOMER INPUT

·Rail: A lifting point is required within 250mm of the rail connection.

·Rail Length L: This refers to the length of the fixed rails on both sides.

·Girder S: This refers to the center-to-center distance between the two fixed rails. The default overhang length is 250mm.

·Hook Coverage: Due to its size, the equipment has a certain blind spot. Users must consider the actual hook coverage requirements. Furthermore, a safe clearance must be reserved for equipment installation and operation, which may vary slightly from the space dimensions.

·Beam Height: This refers to the height of the main beam where the trolley is suspended from the hoist (for free-standing structures, this is usually calculated from the ground or column support point).

·Structural Type and Operation Control Method: The structural type refers to free-standing (foundation thickness) or suspended type. The main beams can be single, double, or telescopic, as well as the required number and load.Operation methods include manual, fully electric, or electric operation of the trolley and trolley. Power supply methods include flat cable, busbar, or C-rail. Control methods include handle control and remote control.

SPECIFIC APPLICATION

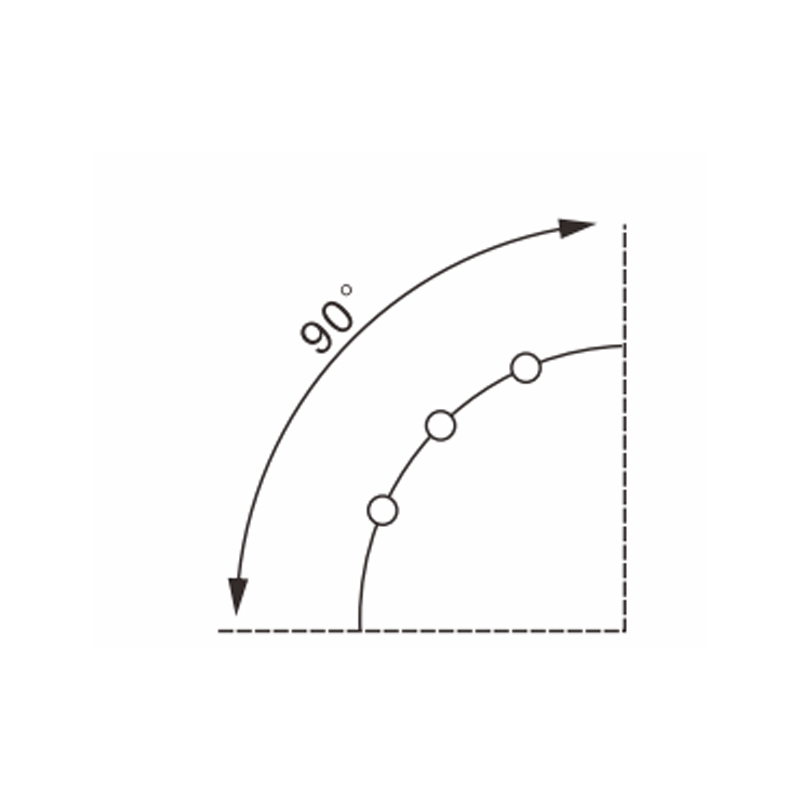

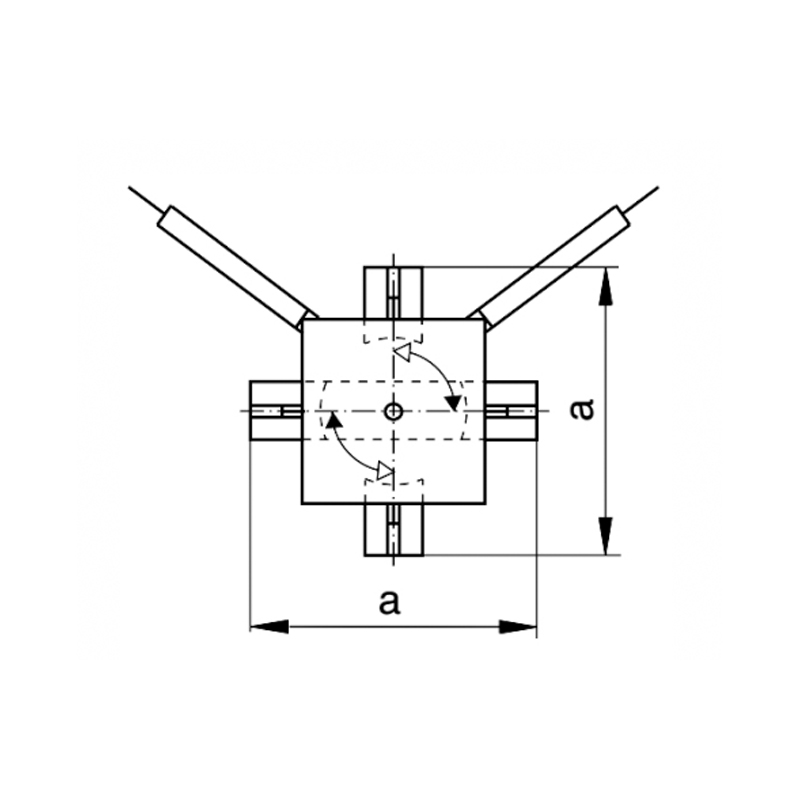

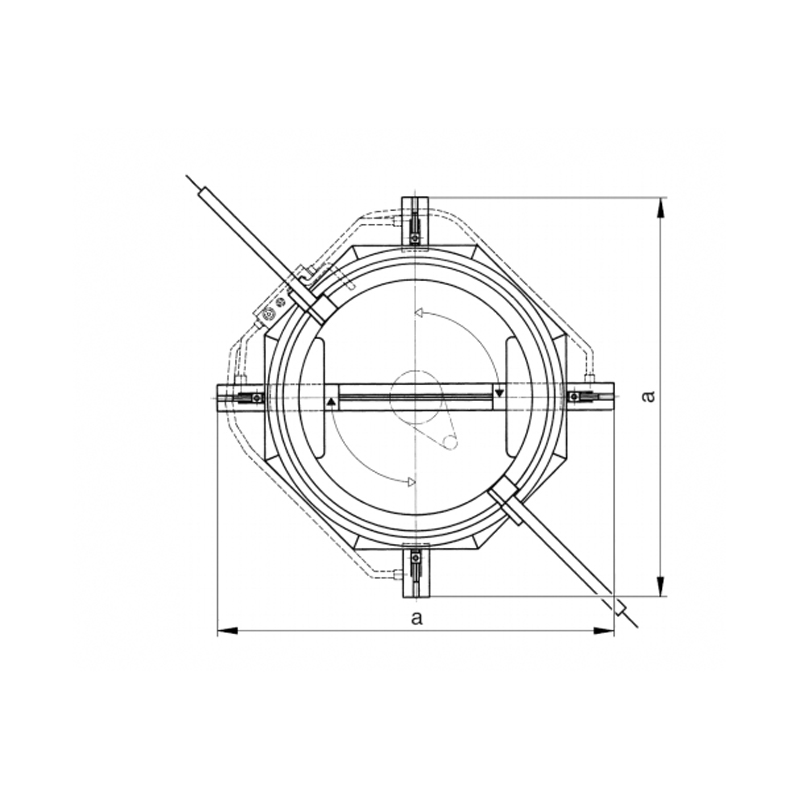

|

Curved Track |

Built-in conductor rails Usually used in special applications such as curved rails, switches, and turntables |

|

Turnout (non-standard design available) |

Built-in busbar (non-standard design available) |

Recommended Products

-

SHA8 Low-headroom Electric Wire Rope Hoist

-

SHA8 Double Girder Electric Wire Rope Hoist(Double reel)-BZ Type

-

SHA8 Double Girder Electric Wire Rope Hoist(Single Reel)-BS Type

-

SHA8 Winch

-

SHA7 Low-headroom Wire Rope Hoist

-

SHA7 Double Girder Electric Wire Rope Hoist

-

SHA7 Standard headroom Wire Rope Electric Hoist

-

Crane End Carriage

-

Crane Wireless Remote Control

-

Crane Conductor System

-

Crane Festoon System

-

Crane Wheel Block

Zhejiang Shuangniao Lifting Equipment Co., Ltd. is a special equipment company specializing in the research and development, production, marketing and after-sales service of wire rope electric hoists. Since its establishment, the company has attached great importance to new product development and technological innovation, and has been focusing on high starting points and high configurations. In the research and development of electric hoist, while continuously introducing foreign advanced technology, it actively develops the research and development of new European-style electric hoist, and establishes the core concept of "innovation leads the future, focus on achieving wonderful", which has become the vane of domestic electric hoist development and leads The development of domestic electric hoist industry.

English

English