Rigid Light Cranes

Manually lifting, combining, or moving relatively light loads is not only time-consuming but also physically demanding. Our shop-mounted jib cranes, combined with a variety of hoists, help you quickly and easily handle a wide range of workpieces and place them gently and precisely. This significantly reduces setup and downtime, eliminating time wasted waiting for the shop crane. Other advantages of column- and wall-mounted jib cranes include:

Suitable for vertical lifting and light, fast load handling

Simple, safe, and reliable operation

Lifting capacity up to 10,000 kg

Easy installation using the system's included assembly hardware.

- Specification

- About TBM

- Contact Us

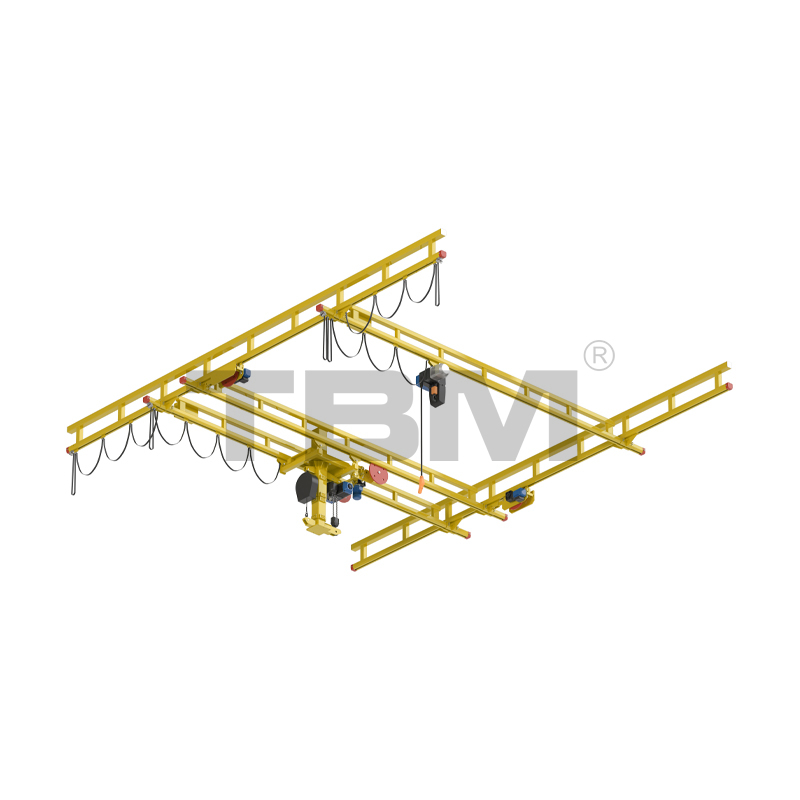

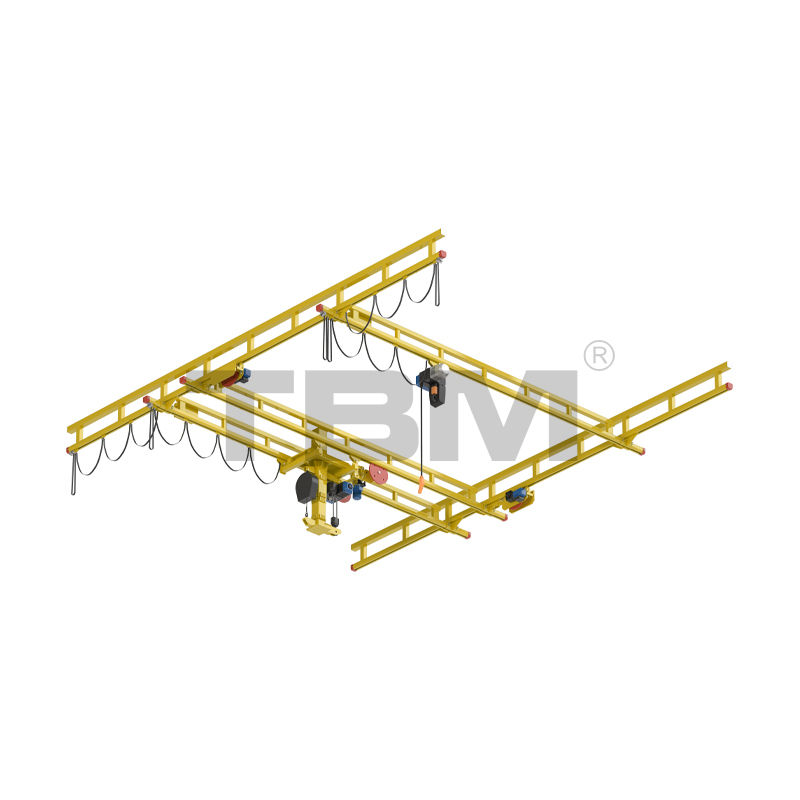

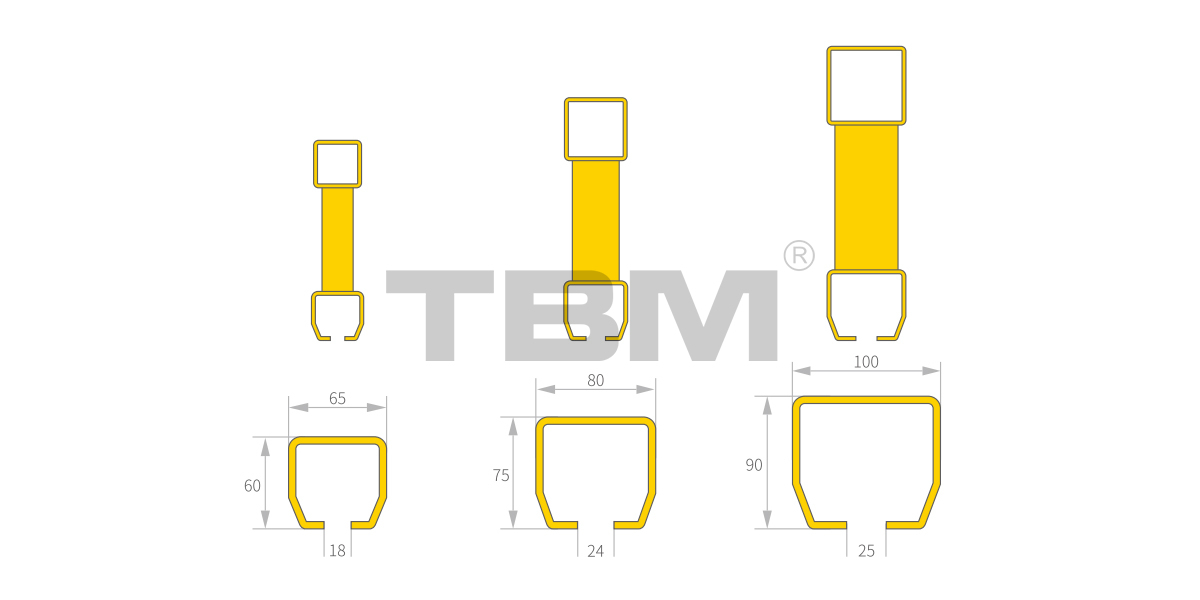

Rigid track structures are truss-type. Three basic track cross-sections can be combined to create a variety of truss configurations. These can be tailored to accommodate varying loads and spans by adjusting factors such as the size of the top chord, web members, and bottom chord (track). The truss structure's high load capacity, large span, excellent stability, and attractive appearance have made rigid track cranes increasingly popular in the light and small lifting industry.

The following are several common structural options:

| Series | Model | Hanging point spacing S/mm | Load/KG | Truss height/mm |

| 60 Series | SRR0263 | S≤6300 | 250 | 255 |

| SRR0276 | 6300<S≤7600 | 250 | 315 | |

| SRR0291 | 7600<S≤9100 | 250 | 365 | |

| 75 Series | SRR0563 | S≤6300 | 500 | 280 |

| SRR0576 | 6300<S≤7600 | 500 | 355 | |

| SRR0591 | 7600<S≤9100 | 500 | 430 | |

| 90 Series | SRR1063 | S≤6300 | 1000 | 335 |

| SRR1076 | 6300<S≤7600 | 1000 | 390 | |

| SRR1091 | 7600<S≤9100 | 1000 | 460 | |

| SRR2063 | S≤6300 | 2000 | 460 | |

| SRR2076 | 6300<S≤7600 | 2000 | 510 | |

| SRR2091 | 7600<S≤9100 | 2000 | 560 | |

| Note: 60 series, 75 series, and 90 series refer to the cross-sectional height of the track. | ||||

RIGID CRANE COMPONENTS

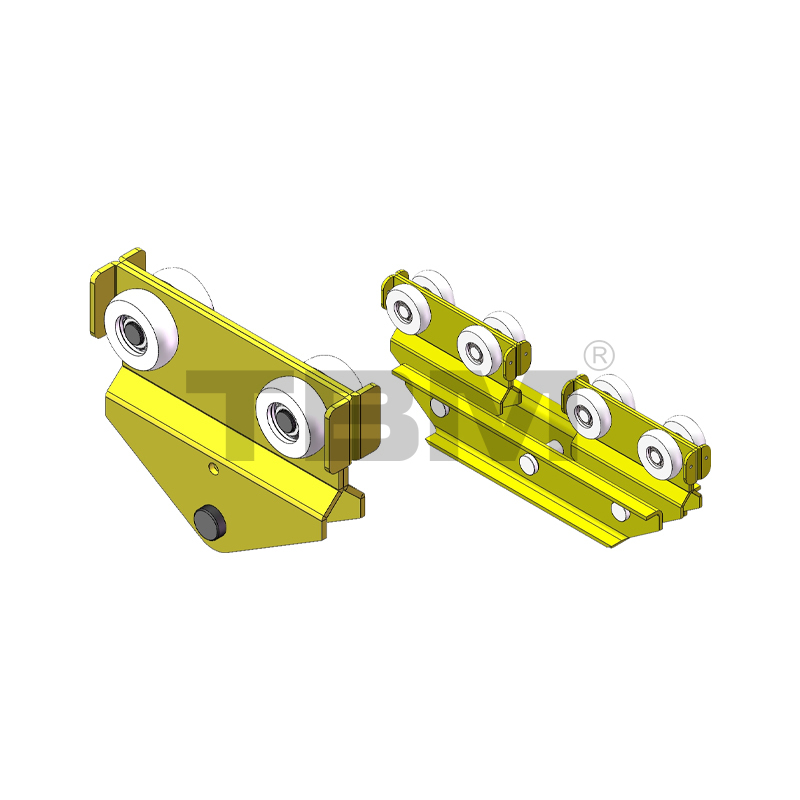

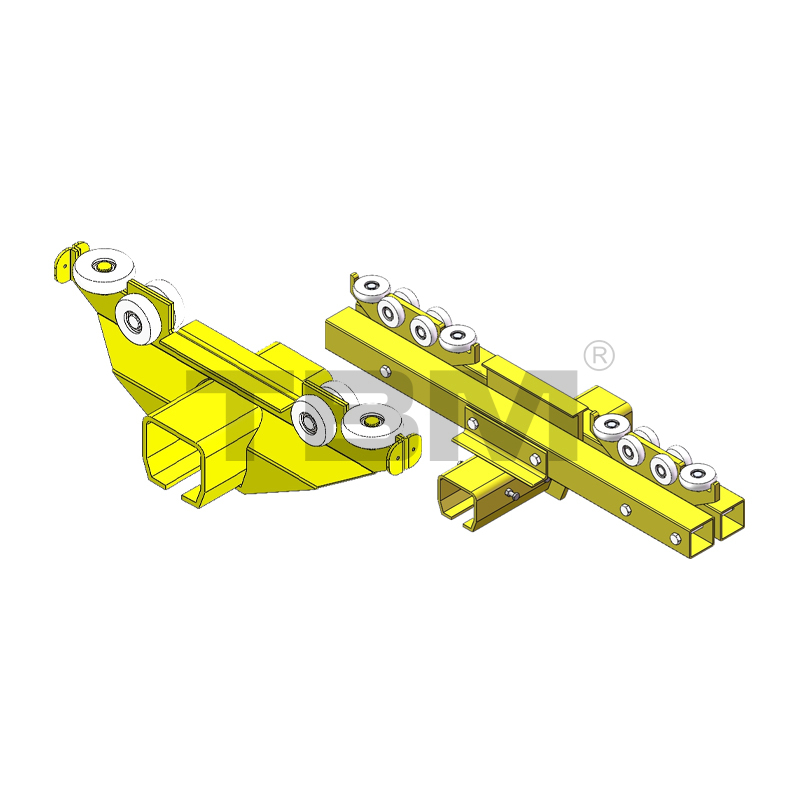

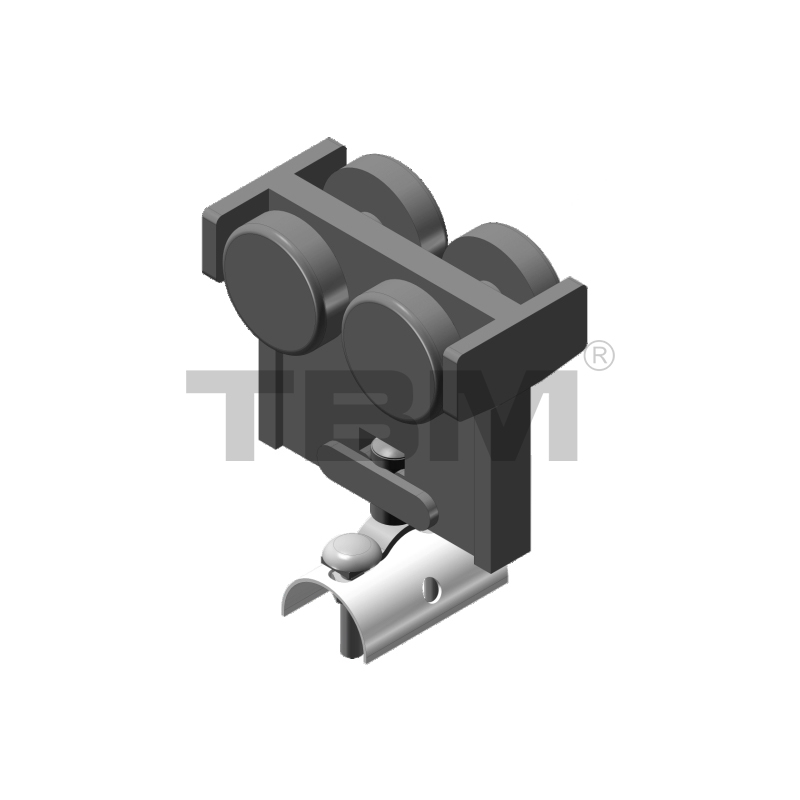

RHT02/05/10/20 Main Beam Trolley

█The main beam trolley is used for hanging lifting mechanisms, etc. Its wheels are made of high-strength nylon and have a corresponding slope, allowing them to conform to the rail tread, ensuring smooth operation and automatic centering. Bent wings at both ends prevent the trolley from accidentally falling off the track, ensuring full safety.

| Model | Load/KG | Applicable track |

| RHT02 | 250 | 60 |

| RHT05 | 500 | 75 |

| RHT10 | 1000 | 90 |

| RHT20 | 2000 | 90 |

| Note: RHT20 trolley is a double trolley plus connection version of RHT10 trolley | ||

RET02/02L/05/05L/10/10L/20L Single-Girder Rail Trolley

■Connects the rail to the main beam. This rigid connection ensures the main beam remains perpendicular to the rail during movement, allowing both sides of the beam to move synchronously without twisting.

| Model | Load/KG | Applicable track | Note |

| RET02 | 250 | 60 series | Main beam length ≤6.5m |

| RET02L | 250 | 60 series | Main beam length ≤6.5m |

| RET05 | 500 | 75 series | Main beam length ≤6.5m |

| RET05L | 500 | 75 series | Main beam length ≤6.5m |

| RET10 | 1000 | 90 series | Main beam length ≤6.5m |

| RET10L | 1000 | 90 series | Main beam length ≤6.5m |

| RET20L | 2000 | 90 series | - |

| Note: L stands for extended type. Under the condition of 2000KG, all rail trolleys are extended type. | |||

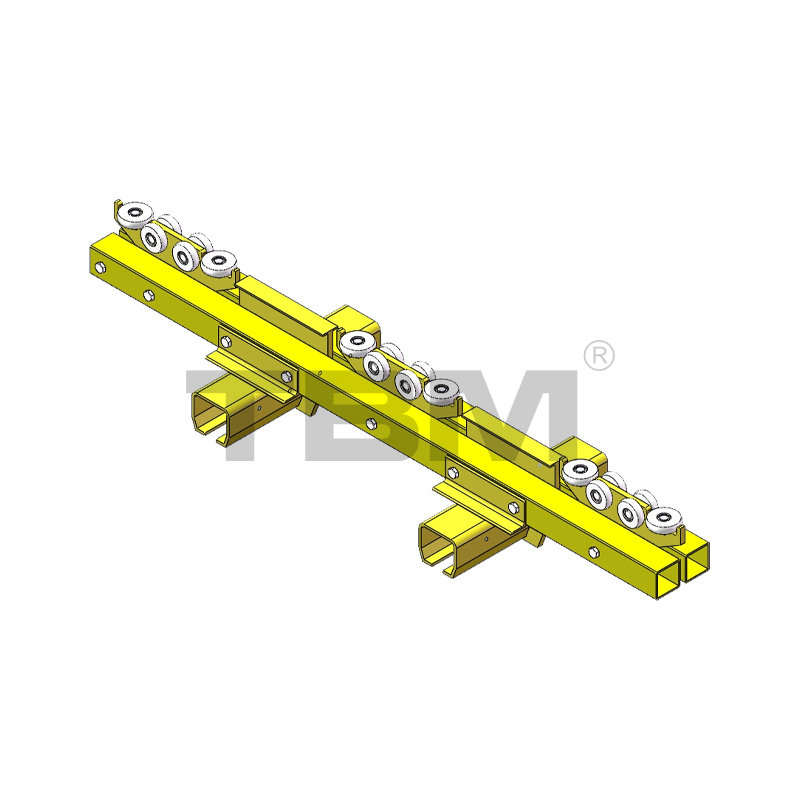

RET60D/75D/90D Double-Girder Rail Trolley

In double-girder construction, the end beam trolley is integrated to ensure consistent spacing between the two beams.

| Model | Load/KG | Applicable track |

| RET02D | 250 | 60 series |

| RET05D | 500 | 75 series |

| RET10D | 1000 | 90 series |

| RET20D | 2000 | 90 series |

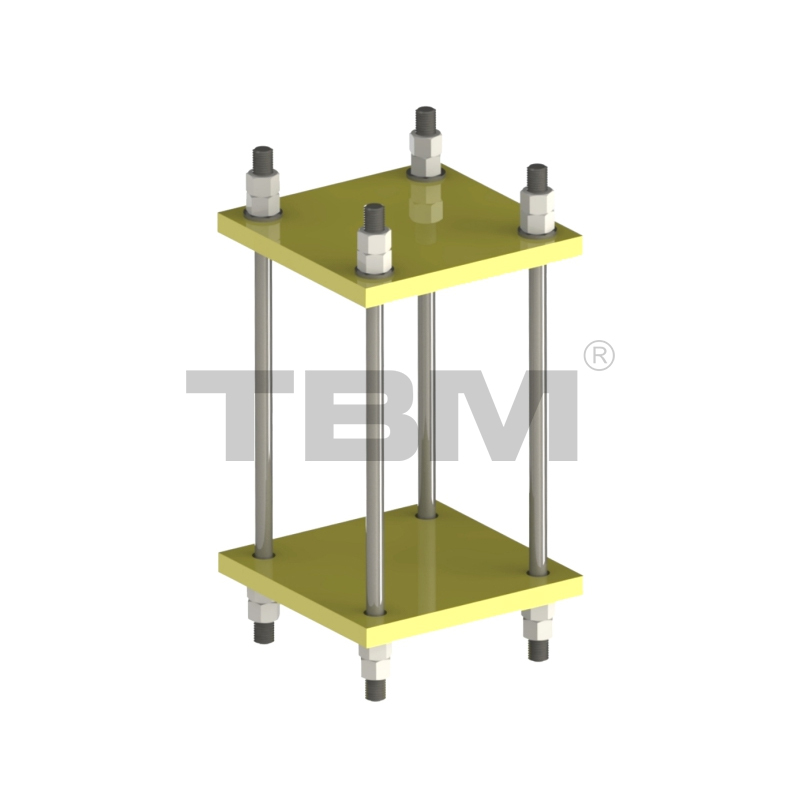

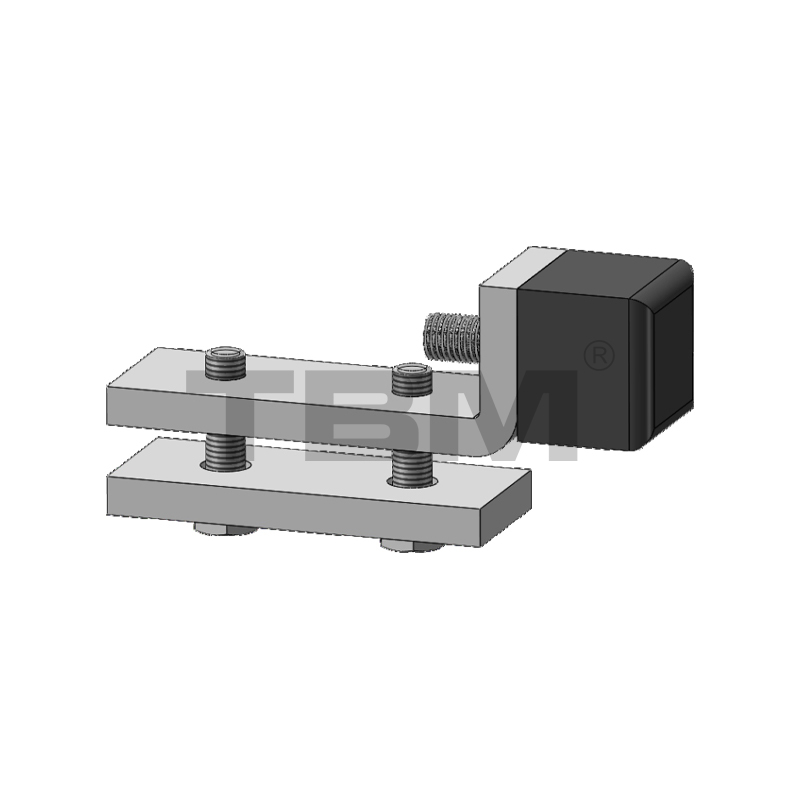

Track Hanger

■Used to securely connect the top chord and crossbeam of a truss. The size and thickness of the track connector's clamping plate vary depending on the load.

| Model | Note |

| RLP02 | Applicable to 60 series rails |

| RLP05 | Applicable to 75 series rails |

| RLP10 | Applicable to 90 series rails |

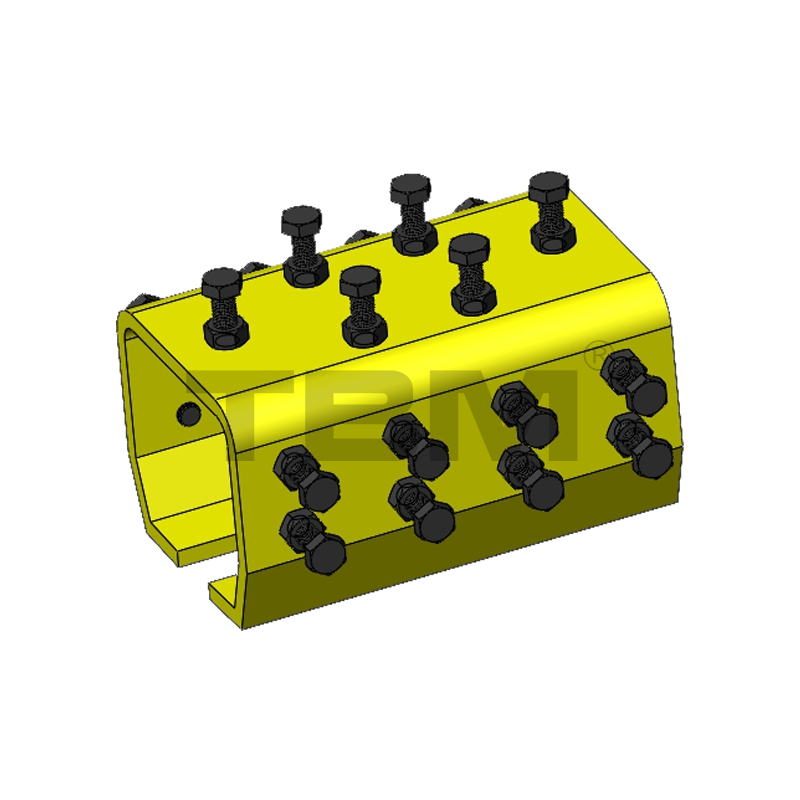

Track Connectors

The three track connector models for the 60, 75, and 90 series are:

RRC02/05/10

[Connectors between two adjacent fixed rails. Adjust the screws above to ensure a smooth connection between the two fixed rails, allowing the trolley to pass smoothly.]

Track End Caps

The three track end cap models for the 60, 75, and 90 series are:

REC02/05/10

■ Track end caps are used to prevent dust and foreign matter from entering and enhance the appearance.

Cable Pulley

Used to suspend and tow cables while the main beam or hoist is traveling.

RCTO1 Cable Pulley

RCE01 Cable Terminal Clamp

External Stops

■Compatible with 60, 75, and 90 track sizes, Model: RAS01

■Adjustable stop positions based on the track's operating area.

RHT02D/05D/10D/20D Double-Girder Trolley Frame

■Default double-girder center spacing is 700mm (special dimensions available upon request).

The double-girder trolley frame evenly distributes the hoist load across the two main beams.

Secondary Protection

To prevent unexpected situations, secondary protection devices are installed on each fixed rail, each main beam, and each hoist. They are categorized as follows:

| Models | Name | Notes/Default Size |

| RDP-R | Track secondary protection | Wire Rope Length 1m |

| RDP-G | Main beam secondary protection | Wire Rope Length 1m |

| RDP-H | Hoist secondary protection | Wire Rope Length 1m |

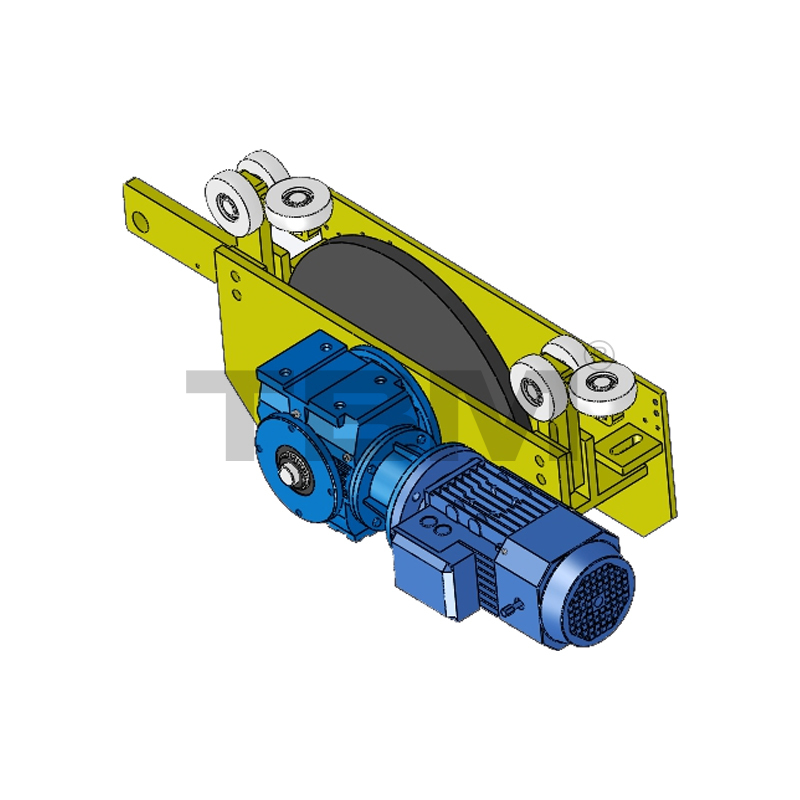

Electric trolley

When the travel mode is electric, the main beam and hoist drive unit.

The motor can be selected from domestic or imported brands.

[Default travel speed: 5-20m/min (variable frequency dual speed)]

| Model | Notes |

| RED01 | Standard premium brand motor |

| RED02 | High-end SEW motor/other |

| RED03 | Custom servo drive motor |

Electrical Control Box

■Control unit for driving the vehicle. Depending on customer requirements, the selected configuration may vary.

The default control configuration is variable frequency.

| Model | Notes |

| REB01 | Standard configuration: premium domestic brand components |

| REB02 | High-end imported brand components |

| REB03 | Customized servo drive configuration |

CUSTOMER INPUT

·Load w

The load of a single main beam, the load of the entire frame

·Rail Length L

Refers to the length of the fixed rails on both sides.

·Girder Span S

Refers to the center-to-center distance between the two fixed rails. The default is 250mm.

·Beam Height H

The height of the main beam trolley's hoist (for free-standing structures, usually calculated from the ground or column support point).

·Hook Coverage

Due to its size, the equipment has certain blind spots. Users must consider the actual hook coverage requirements. Furthermore, a safe clearance must be reserved for equipment installation and operation, which may vary slightly from the space dimensions.

·Structural Type and Operation Control Method

Structural type refers to free-standing (foundation thickness) or suspended type. Main beams can be single, double, or telescopic, and the required number and load are also included. Operation methods include manual, fully electric, or electric operation of the trolley and trolley. Power supply methods include flat cable, busbar, or C-rail. Control methods include handle control and remote control.

Recommended Products

-

SHA8 Low-headroom Electric Wire Rope Hoist

-

SHA8 Double Girder Electric Wire Rope Hoist(Double reel)-BZ Type

-

SHA8 Double Girder Electric Wire Rope Hoist(Single Reel)-BS Type

-

SHA8 Winch

-

SHA7 Low-headroom Wire Rope Hoist

-

SHA7 Double Girder Electric Wire Rope Hoist

-

SHA7 Standard headroom Wire Rope Electric Hoist

-

Crane End Carriage

-

Crane Wireless Remote Control

-

Crane Conductor System

-

Crane Festoon System

-

Crane Wheel Block

Zhejiang Shuangniao Lifting Equipment Co., Ltd. is a special equipment company specializing in the research and development, production, marketing and after-sales service of wire rope electric hoists. Since its establishment, the company has attached great importance to new product development and technological innovation, and has been focusing on high starting points and high configurations. In the research and development of electric hoist, while continuously introducing foreign advanced technology, it actively develops the research and development of new European-style electric hoist, and establishes the core concept of "innovation leads the future, focus on achieving wonderful", which has become the vane of domestic electric hoist development and leads The development of domestic electric hoist industry.

English

English